HYDRAULIC DIVERTER

A hydraulic diverter is an essential element of any hydraulic system. The hydraulic diverter is actually a valve that has been designed to control the direction of movement of the fluid in the system. A very important function of the manifolds is to relieve the pump during system breaks.

In a situation where there is a sudden lack of fluid flow in the hydraulic system, the diverter protects the pump against overloading. In addition, this valve allows you to control the position of the pump in the system.

A hydraulic diverter can be found in agricultural and industrial machines. In these devices they are used to redirect the working fluid (usually hydraulic oil) to a specific place in the system. Another task is to lead the liquid to another element of the system. A hydraulic diverter is usually mounted between the supply element and the receiver - this can be, for example, a place between the pump and the engine. These elements are connected with each other using hydraulic hoses and other fasteners.

.JPG)

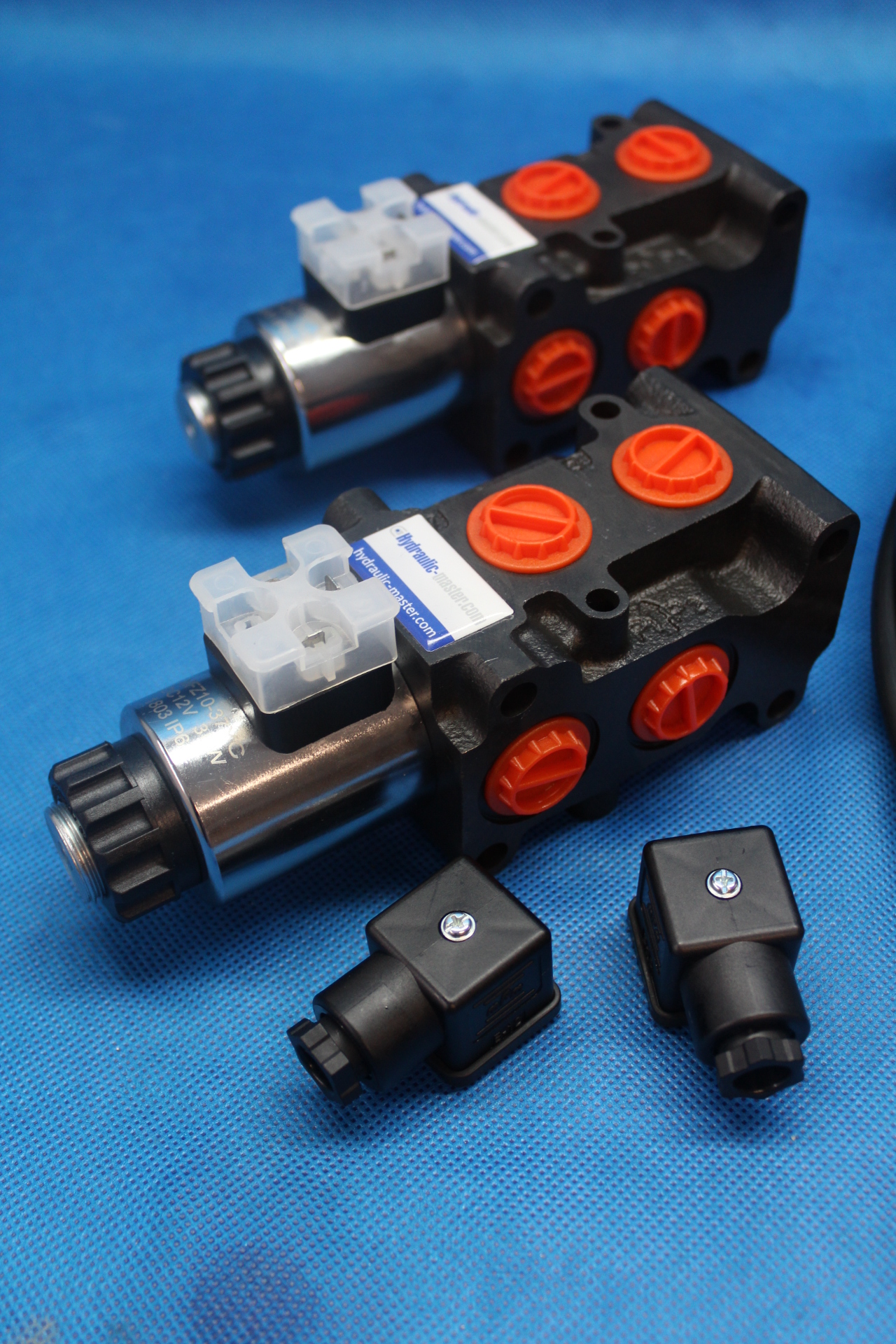

Hydraulic diverters can be divided into directional spool valve, socket and intrinsically safe. The differences between these diverters are due to design solutions. The slide manifold bases its work on the operation of the slide. It moves inside the cylinder, while its position is responsible for the regulation of the working fluid flow inside the device. The directional spool valve can be electrically or mechanically controlled. The socket manifold regulates the movement of liquids using a special ball (valve). Depending on the needs, the ball can completely open or close the fluid flow. The last type of distributors, i.e. intrinsically safe, is a device that can be used in places with a high degree of explosion risk (e.g. in mines). Inside the intrinsically safe distributor there are pistons that move when the voltage on the control coil.

There is also a division of manifolds by type of construction. We can divide them into monoblock and block ones. Monoblock manifolds withstand a much higher pressure level compared to block manifolds.

We can distinguish one-, two- and three-section hydraulic diverters. Diverters can also be extracted based on differences in control method. Speaking of manifolds in the context of the control method, manual and electric models can be found.

Hydraulic diverters are commonly used in various types of pneumatic systems. In addition to agriculture, they are also used in mining and industrial machines. A hydraulic diverter is an essential element of, among others, a forklift. Hydraulic diverters are devices without which it will not be possible to work the baler press, loaders, as well as a number of other agricultural machines.

Why diverters are such an indispensable element of industrial machines? The work of a hydraulic diverter can be compared to a controller. Its main task is to activate and stop the flow of liquid in the system.

.JPG)

_1.JPG)

_1.JPG)