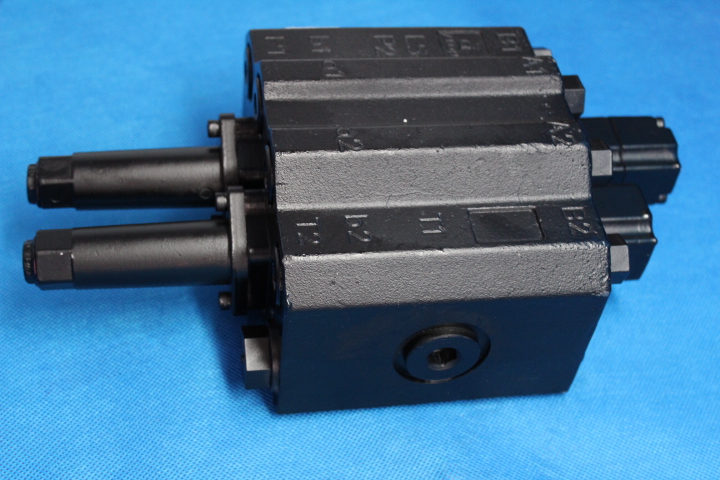

LOADER CONTROL VALVE

The loader control valve is intended to control the lifting and loader equipment. The loader control valve is equipped with a "joystick", i.e. a control lever, which is located at the operator's seat. The lever is connected to the hydraulic control valve via two control cables.

The control valve is an electric valve installed on the front of the loader. It is designed for loader accessories with hydraulic functions and for loaders equipped with a hydraulic attachment lock. The valve is controlled by one control lever that controls all functions.

The charger is equipped with many elements that ensure work safety. These elements include valves that prevent uncontrolled boom dropping and fork carriage movement, as well as a load indicator that is located in the operator's cab to indicate forward stability.

The control valve finds its application in special vehicles such as loaders, truck cranes, shredders, scrubbing machines and dynamic compactors. The control valve can effectively control the actuating mechanisms, i.e. engine and oil cylinder.

Valves used to control the direction, speed and pressure of hydraulic lines are used in most air and hydraulic oil supply systems. Some valves can regulate flow while allowing it to pass through a different section, while other types are designed to simply allow flow to pass, stop or change direction. Traditional flow control valves will have a variable aperture value that can close to slow down the flow or open to increase the flow. The flow control valve offers increased functionality compared to a traditional control valve, and allows pressure and flow regulation.

The pneumatic flow control valve is mainly used to regulate pressure or fluid flow. The flow control valve is part of the pneumatic circuit, while the function of such valves is to reduce the flow rate in a specific section, which then results in a slower drive speed.

The flow control valve works as follows. The flow is directly proportional to the speed, while the pressure is directly proportional to the strength. When the flow to the actuator increases, its speed will increase. If the available pressure increases, the available strength increases as well. The flow changes the rotation speed of the actuator, while the pressure changes the force of the actuator, and the position of the valve changes the direction of the actuator.

.JPG)