RC 400 RADIO REMOTE CONTROLLER WITH 6 FUNCTIONS FOR HIAB PALFINGER ATLAS FASSI RETRO KIT FOR LEVERS VALVE 24V

6 Functions.

Customer-specific configuration, fully customisable.

Contact us and we will adapt the radio control to your machine.

- Share this:

- Secured Payment

- Fast Delivery

- 24/7 Tech Support

RC 400 RADIO REMOTE CONTROLLER WITH 6 FUNCTIONS FOR HIAB PALFINGER ATLAS FASSI RETRO KIT FOR LEVERS VALVE 24V

- Touch on Image to show all photos

6 Functions.

Customer-specific configuration, fully customisable.

Contact us and we will adapt the radio control to your machine.

Informations

Scanreco RC400 Radio Remote Control Systems.

The Scanreco RC 400 G2B remote control system has been especially developed for

hydraulically driven mobile cranes and machinery. The system is a digital remote

control system based on an extremely advanced microprocessor technology. Years of

exhaustive and demanding testing have shown that the remote control system can

cope with the roughest of environments.

The system is protected against electromagnetic and radio frequency radiation and

can be installed onto all hydraulic valve types (voltage, current pulse width, or

protocol steered) found on the market.

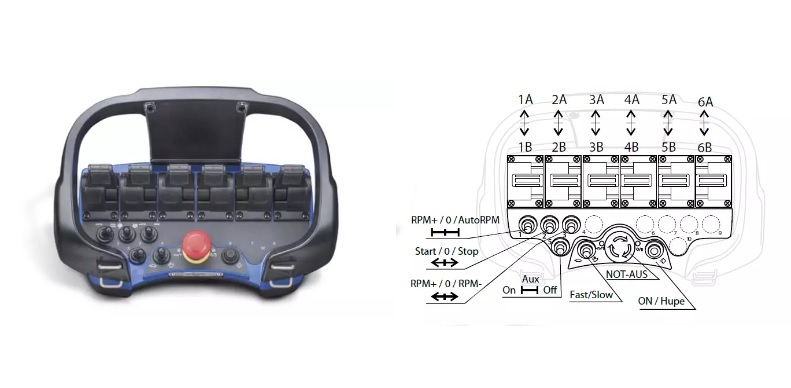

In its basic form the remote control system is comprised of a portable control unit

with manoeuvre levers for proportional control and switches for ON/OFF functions, a

central unit with connection cable for driving proportional electro-hydraulic slide

controllers.

Digitally coded control information (lever deflection and switch position) is sent from

the portable control unit via radio to the central unit. The portable control unit and

central unit translate the magnitude and direction of the manoeuvre lever deflections

and switch position.

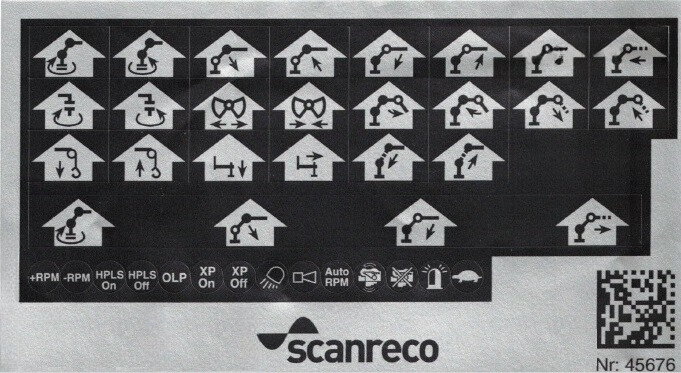

It can be used for four typical proportional functions, e.g.

-Slewing (rotation of crane)

-Main lift

-Jib

-Extension

-Grab open / close

-Rotator

You can also choose a different function as below:

|

Extremely easy to use, safe, fast and precise; its electronic core, based on advanced microprocessor technology, is highly configurable.

If you have crane with valve manually controlled by levers this kit is for you. Extremely easy to use, safe, fast and precise; its electronic core, based on advanced microprocessor technology, is highly configurable.

With this kit you stay with your old hydraulic valve and control crane with remote radio.

However the kit complete does not need such a high quality valve. This kit comes with a servo unit that connects to the con rods or directly to a standard control valve and replicates the users hands pushing and pulling the levers. The servo unit will connect to the original control valve on the crane or the connection rods to the auxiliary side.

|

The "Mini" is a compact and versatile transmitter that can be easily adapted to customer requirements. Thanks to its modular design, the "Mini" can be supplied with either 1 to 6 linear levers or 1 to 3 joysticks and additional buttons and switches. Despite the compact format, all operating elements are sufficiently large and designed for long and fatigue-free operation.

In addition to standard functions, the transmitter also offers numerous optional settings and functions for optimum operator guidance. The speed of proportional movements can be set in five stages using a latching switch. The operator receives feedback from the controlled machine via the display and LEDs. Automatic frequency management ensures trouble-free operation even in the event of interference from other radio devices in the vicinity. On-site calibration allows authorized users to adjust system settings without additional tools or software. The transmitter has an individual identification code and communicates with the receiver via a proprietary protocol. This ensures that no other transmitters (from Scanreco or other manufacturers) can accidentally activate the machine. The tamping function complies with performance level "e" (PL e), the highest level according to ISO 13849-1, a legally binding standard for safety-critical control components.

|

The "G2" receiver is available with proportional and digital outputs as well as a CANopen interface. Thanks to its numerous interfaces and setting options, the "G2" is suitable for practically all mobile hydraulic applications. The analog output signals can control voltage and current-controlled hydraulic valve blocks. Several receivers can be connected together in a master-slave configuration if more functions are required than a single receiver can provide. The numerous functions of the integrated basic controller support a wide range of performance and functions. The basic controller makes it possible to dispense with numerous external electronic components (PLC, relays, diodes, etc.).

|

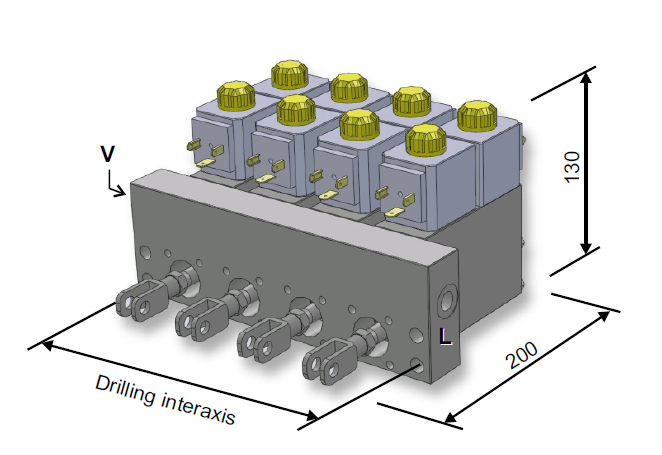

MOD10 proportional servocontrols actuator block.

The hydraulic bank MOD10 electrohydraulic system, when coupled with a manual hydraulic distributor, allows for remote control.

The bank is made up of a manifold with mounted on as much sections (modules) as the movements to activate. All the modules are identical and they are fixed to the manifold with four screws stay. Each module works as standalone.

The coupling of the hydraulic bank pistons to the manual distributor, already mounted on the machine, is done by brackets to screw on the dual control rods which have to be coupled with the forks mounted on each piston.

It is possible to connect the forks to a different leverage system as long as is guaranteed, with right slots, an enough play to prevent stress in different direction than the axial one.

The product has a high reliability.

The installation of this block adds to a hydraulic valve the remote control, by cable or by radio. The specific design for the dual control rods allows its installation on any type of hydraulic mechanical valve.

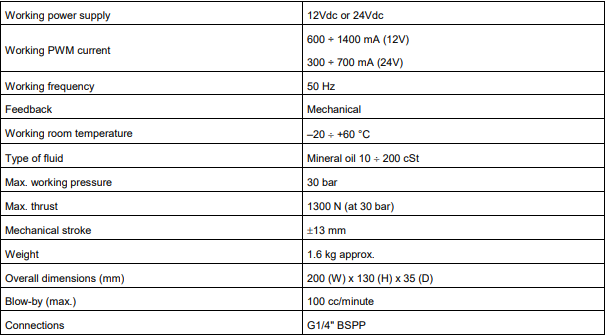

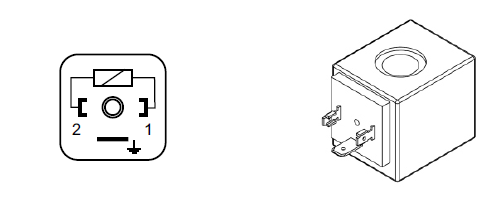

Electrical specifications:

PWM solenoids (voltage signal)

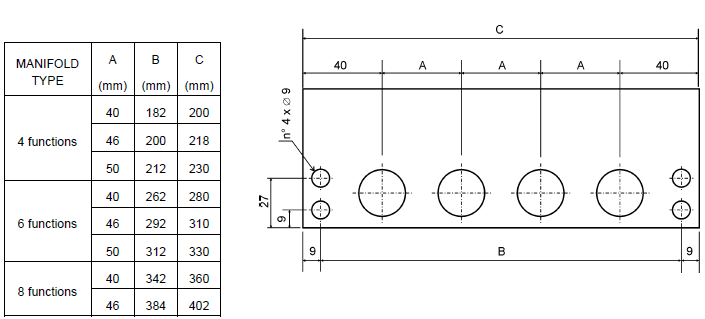

The MOD10 offers 3 section spacing options; please specify which one you choose when purchasing.

|

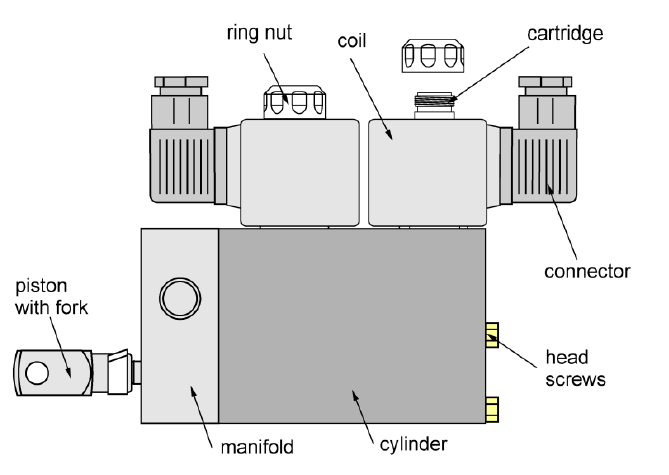

Each module is made up of a hydraulic cylinder commanded by two proportional valves with mechanical feedback.

|

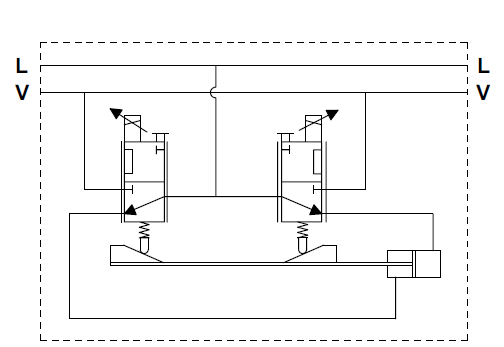

Hydraulic scheme:

|

Electrical connections:

|

Perfect for 6 functions HIAB, JONSERED, PICKER, HMF, ATLAS, FASSI, PALFINGER, but it also works with many other brands.

Note! After your buy please inform us about serial numer of your crane ond type of valve then we add right electric plugs.

Volume discounts

| Quantity | Unit discount | You Save |

|---|---|---|

| 5 | 10% | $3,450 |

| 10 | 15% | $10,350 |

| 20 | 25% | $34,500 |

Do you need help?

Looking for a non-standard product?