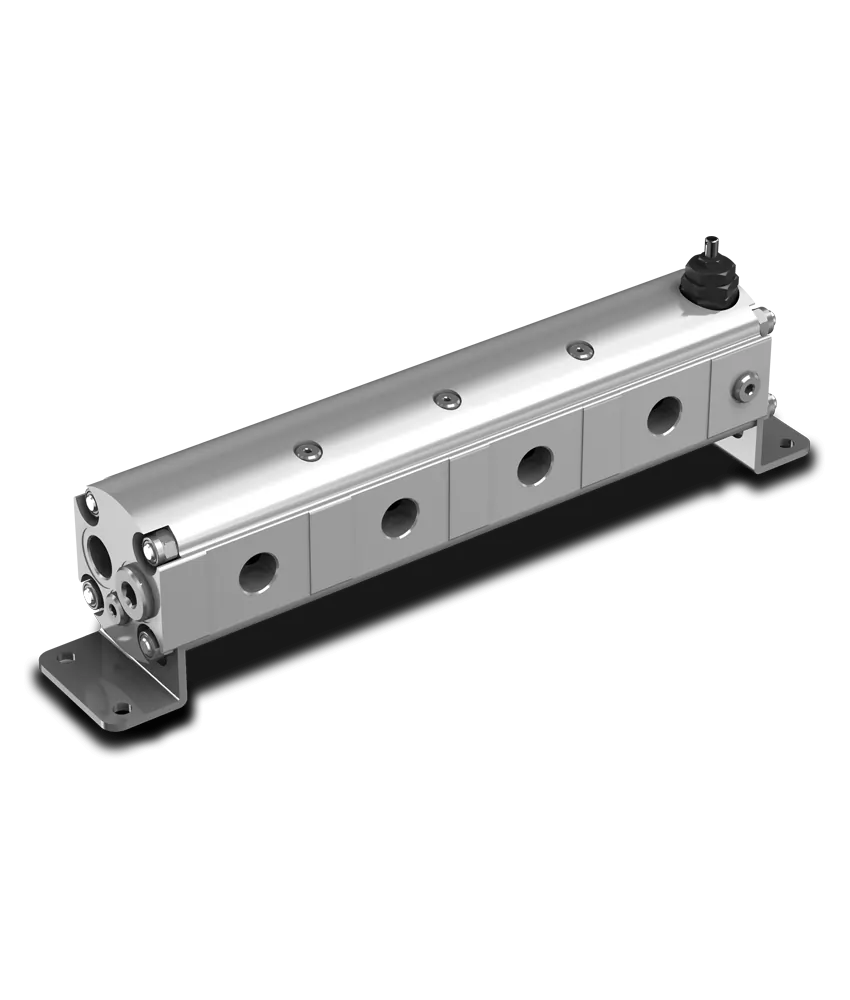

ALUMINIUM GEAR PUMPS

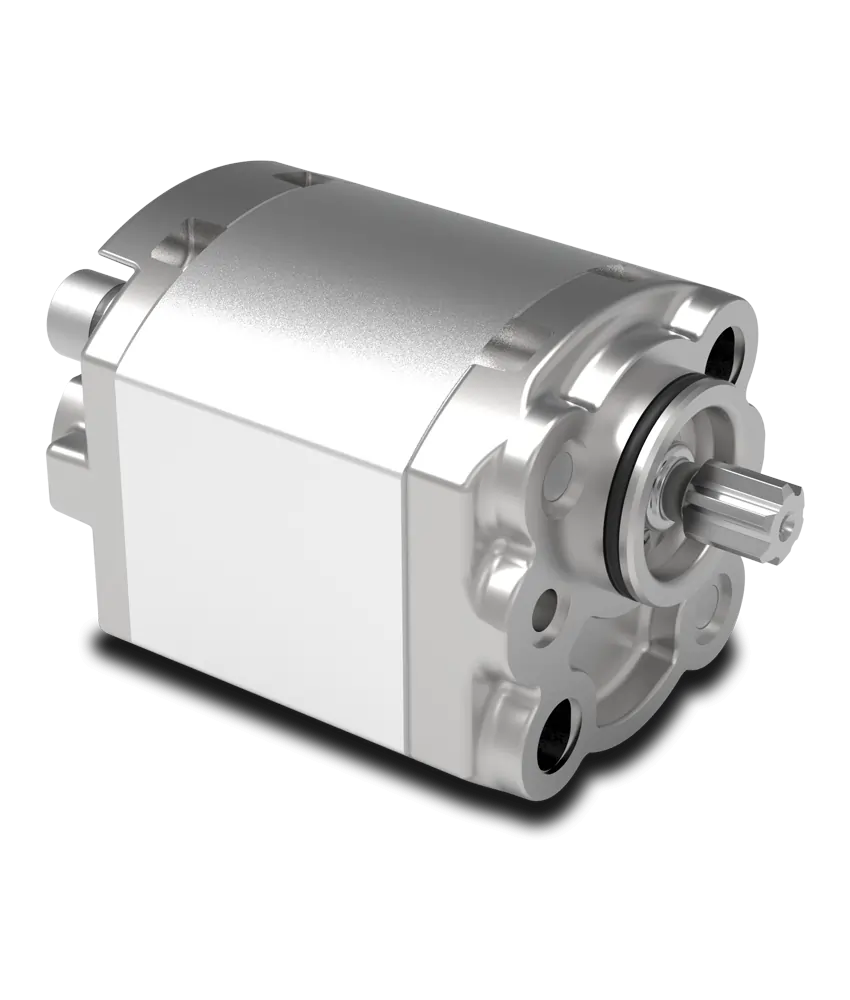

ALUMINIUM GEAR PUMP 1SP - GROUP 1

Now introducing the Walvoil 1SP series, coming from Group 1, which consists of high performance, three-piece pumps with an aluminum body and flanges. These are pumps catered to flexibility and efficiency in an extensive number of applications in which hydraulic power is a must.

Versatile configuration and high compatibility: The series 1SP pumps are of both single and multiple pumps configurations in order to adapt with the variety of system requirements. They are designed in a way so that they can stack with those of other families and this is a feature which is not available anywhere else in designing hydraulic systems.

Wide range of Shafts and Flanges: 1SP series allows a combination of a wide range of shafts and flanges options, suitable for numerous types of machinery and easy integration into all fields of application. This is supported by the configurations with integrated valves, offering clean solutions to highly complicated hydraulic systems.

Optimized Performance for Group 1: The 1SP series pumps offer a displacement range from 0.89 cm³/rev up to 9.78 cm³/rev (from 0.05 in³/rev up to 0. It represents an efficient designed pump, to work under the maximum pressures reached at the level of 260 bars (3750 psi), and assures the maximum speed of up to 6000 revs per minute.

Aluminum Build for Durability and Efficiency: Building with aluminum in the construction of the body and flanges not only reduces the weight of the pump—ideal for applications where weight-saving is paramount—but also ensures great durability with superb corrosion resistance. This ensures that the pump operates efficiently throughout its life.

The 1SP series of Walvoil Group 1 hydraulic pumps represents the current state-of-the-art technology level which means flexibility, high performance, and reliability at an impressive level. It presents a variety in wide and diversified fields of applications that range from industrial to mobile. That is to say, in the ultimate occasion of a one-pump setup or multiple pumps, the 1SP series is ready to respond to state-of-the-art machine hydraulics requirements with efficiency and precision.

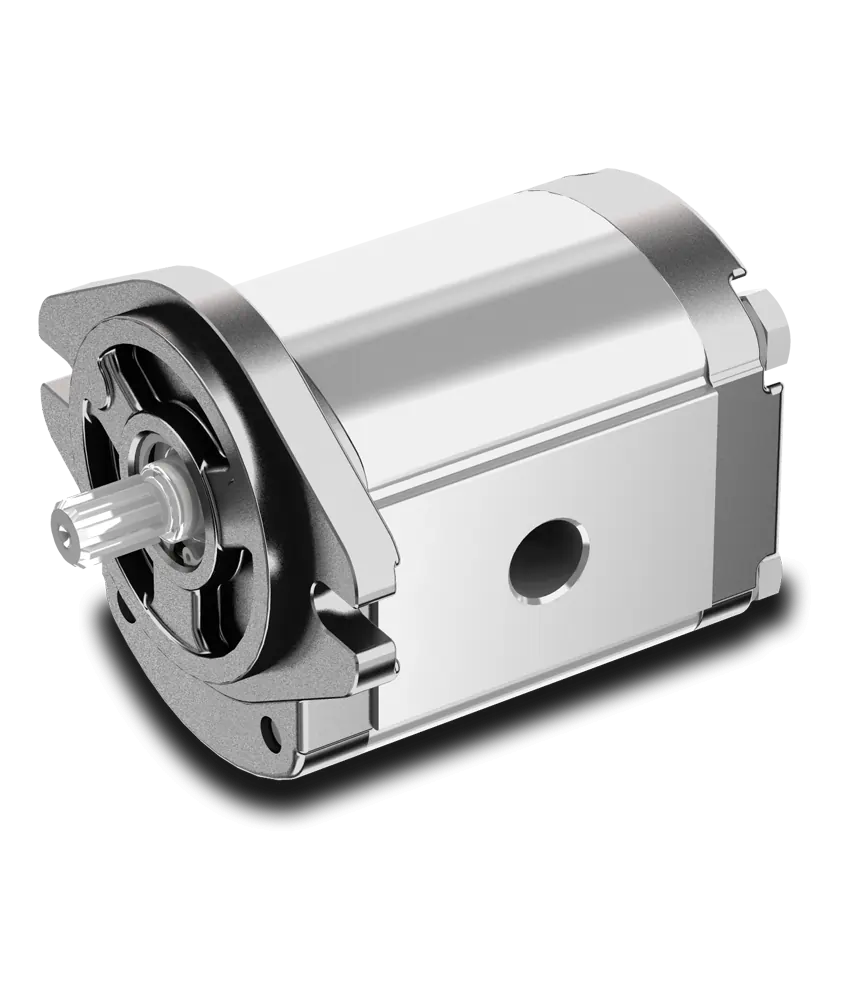

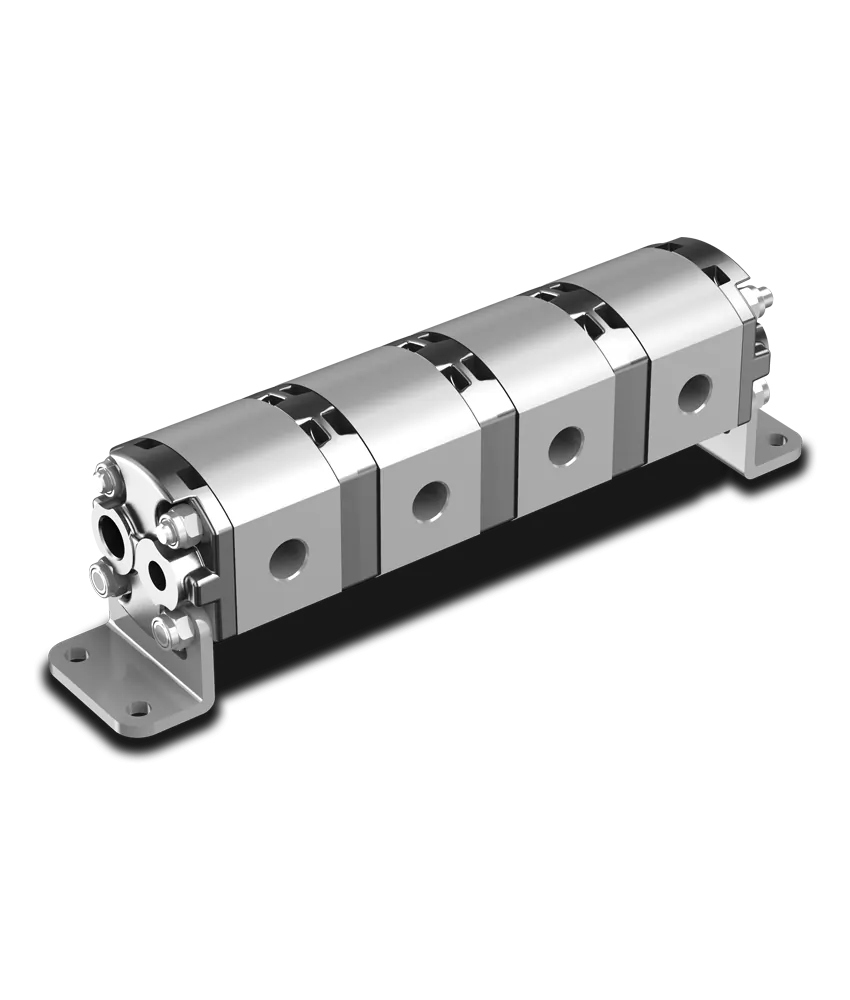

ALUMINIUM GEAR PUMP 2SP - GROUP 2

Introducing the 2SP Series from Group 2, a line of versatile three-piece pumps that epitomize the blend of robustness and flexibility with their aluminum body construction and the choice of aluminum or cast iron flanges. These pumps are designed for adaptability in a wide array of hydraulic applications and are available in single or multiple pump configurations.

Stackable Across Pump Families: The 2SP Series pumps are uniquely compatible with pumps of different families, allowing for a diverse range of stackable options. This stackability ensures that users can combine these pumps for complex hydraulic systems, providing a tailored solution for various requirements.

Displacement Range: With a displacement range from 4 cm³/rev to 31.5 cm³/rev (from 0.24 in³/rev to 1.92 in³/rev), the 2SP pumps cater to a wide spectrum of flow rates within Group 2, accommodating a host of application needs from moderate to high flow requirements.

High-Pressure Performance: These pumps are capable of operating at pressures up to 250 bar (3600 psi), making them suitable for demanding applications that require reliable high-pressure performance.

High-Speed Capabilities: The 2SP pumps can achieve rotation speeds up to 4000 rpm, providing the efficiency and responsiveness needed for applications where system speed is crucial.

Diverse Shaft and Flange Options: With a wide range of shafts and flanges available, the 2SP Series ensures compatibility with numerous drive requirements, offering flexibility for integration into different machines and equipment setups.

Integrated Valve Configurations: To enhance their functionality, the pumps can be configured with integrated valves, streamlining hydraulic systems and reducing the need for additional components.

The 2SP Series pumps from Group 2 are engineered to meet the needs of today's demanding hydraulic systems, offering the perfect combination of performance, versatility, and durability. Whether for agricultural machinery, industrial applications, or mobile equipment, these pumps deliver reliable hydraulic power in a design that is both robust and adaptable.

ALUMINIUM GEAR PUMP 2XP - GROUP 2

The 2XP Series represents an innovative advancement in the Group 2 range of pumps, featuring an aluminum body coupled with robust cast iron flanges. This new series stands out with its oversized shaft design, making it particularly well-suited for applications where traditional aluminum pumps are pushed to their limits.

Enhanced Durability with Oversized Shaft: The oversized shaft in the 2XP pumps addresses the common limitations of aluminum pumps in demanding environments, providing increased strength and reliability. This makes the 2XP Series ideal for applications requiring more robust performance without stepping up to a larger pump size or different material.

Modular Construction for Increased Versatility: The modular construction of the 2XP Series not only increases the versatility of these pumps but also retains compatibility with the existing configurations of the 2SP Series. This ensures that users have access to new options without sacrificing the familiarity and proven performance of the 2SP design.

Consistent Displacement Range: The 2XP pumps offer a displacement range from 4 cm³/rev to 31.5 cm³/rev (from 0.24 in³/rev to 1.92 in³/rev), matching the flexibility and adaptability of the 2SP Series to cater to a wide spectrum of flow rate requirements within Group 2.

High-Pressure Capability: With the capacity to operate at pressures up to 250 bar (3600 psi), these pumps are equipped to handle high-pressure applications, providing consistent and reliable hydraulic power where it is most needed.

Optimal Speed Performance: The ability to perform at rotational speeds of up to 4000 rpm ensures that the 2XP pumps can meet the requirements of high-speed operations, maintaining efficiency and effectiveness in a variety of application settings.

In essence, the 2XP Series from Group 2 stands as a new benchmark in hydraulic pump technology, offering the perfect balance between enhanced performance and the trusted configurations of the 2SP Series. These pumps are ideally positioned to deliver reliable, high-strength performance in applications where traditional aluminum pumps reach their performance threshold, all while offering new modular possibilities and maintaining established design principles.

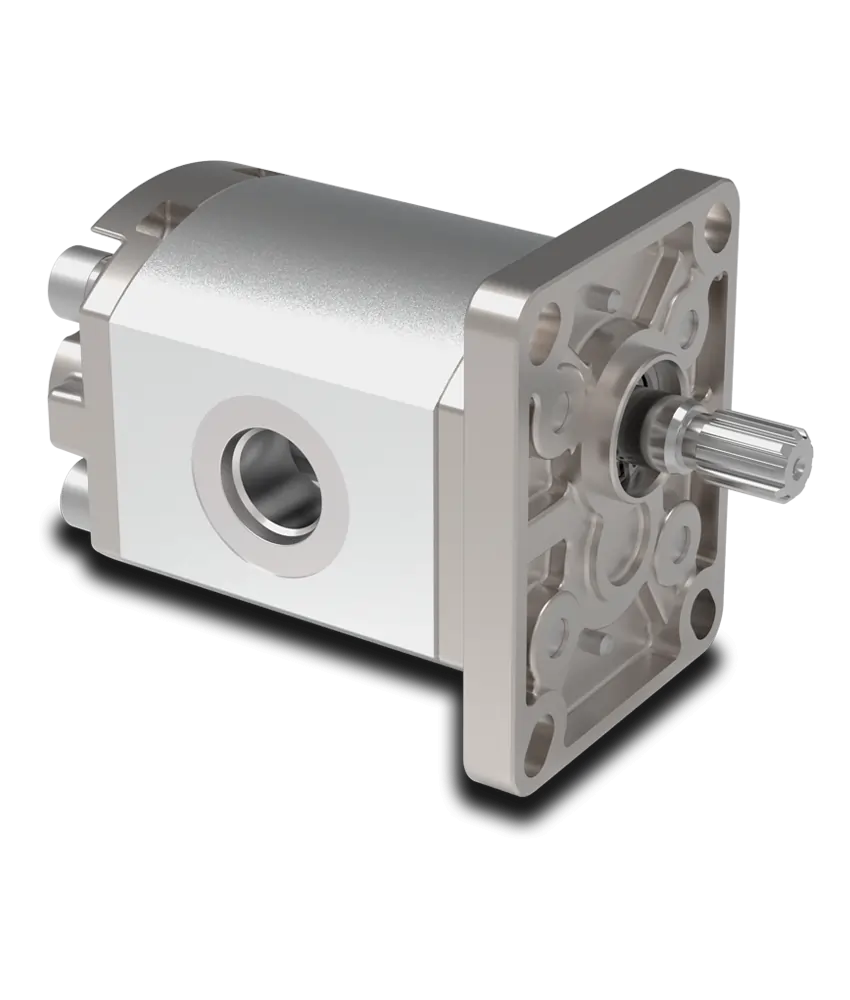

ALUMINIUM GEAR PUMP 3GP - GROUP 3

The 3GP Series from Group 3 is a sophisticated lineup of three-piece pumps characterized by their durable aluminum body and the option for aluminum or cast iron flanges. These pumps are engineered for versatility and robust performance, suitable for a range of demanding hydraulic applications, and available in both single and multiple pump configurations.

Modular Design for System Flexibility: The 3GP pumps are designed to be stackable with other pumps from different families, offering unparalleled flexibility in creating complex hydraulic systems tailored to specific needs and requirements.

Broad Displacement Range: Catering to a diverse range of operational volumes, the 3GP Series provides a displacement spectrum from 19.3 cm³/rev to 77.2 cm³/rev (from 1.2 in³/rev to 4.7 in³/rev). This range accommodates various flow rates and pressure requirements within Group 3 specifications, ensuring optimal performance for various hydraulic systems.

High-Pressure Operations: With a maximum pressure rating of up to 250 bar (3600 psi), these pumps are built to perform reliably under high-pressure conditions, suitable for applications that demand robust power delivery.

Efficient Speed Performance: The 3GP pumps maintain efficiency with rotational speeds reaching up to 3500 rpm. This high-speed capability ensures the pumps can meet the performance requirements of fast-paced applications where timing and response are critical.

Customizable Shaft and Flange Options: A wide selection of shafts and flanges is available to ensure compatibility with a multitude of drive configurations. This variety allows the 3GP Series to integrate seamlessly into different machinery and equipment systems.

Integrated Valve Options for Streamlined Systems: The pumps can be equipped with integrated valve configurations, simplifying the hydraulic system design and minimizing the need for additional components. This integration can lead to more compact system designs and potentially reduced installation and maintenance costs.

In essence, the 3GP Series from Group 3 represents the apex in hydraulic pump technology, offering a combination of strength, adaptability, and performance. These pumps are designed to cater to a wide range of heavy-duty applications, providing reliable and efficient hydraulic power in a flexible, modular design. Whether used in agricultural, industrial, or mobile applications, the 3GP pumps are poised to deliver top-tier performance and system compatibility.

ALUMINIUM GEAR MOTORS

ALUMINIUM GEAR MOTOR 1SM - GROUP 1

Introducing the 1SM Series from Group 1, a collection of unidirectional and reversible motors characterized by their sturdy three-piece construction, featuring an aluminum body and flanges. These motors are engineered for durability and flexibility, designed to accommodate a diverse array of industrial and mobile applications.

Versatile Design for Varied Applications: The 1SM motors offer a wide selection of shafts and flanges, ensuring compatibility with a multitude of equipment configurations. This versatility is further enhanced by the availability of configurations with integrated valves, streamlining the system and potentially reducing the need for additional components.

Optimized Displacement Range: The displacement range for the 1SM motors spans from 0.89 cm³/rev to 9.78 cm³/rev (from 0.05 in³/rev to 0.60 in³/rev), allowing for precise control of motor speed and torque across various applications, from light-duty machinery to more demanding hydraulic tasks.

High-Pressure Capability: With the ability to operate at a maximum pressure of up to 260 bar (3750 psi), the 1SM motors are capable of handling high-pressure environments, ensuring reliable performance under rigorous operational conditions.

High-Speed Performance: The motors are designed to operate at speeds of up to 6000 rpm, catering to applications that require fast and efficient power delivery. The high rotational speeds make these motors suitable for tasks that need quick response and consistent power output.

The 1SM Series motors from Group 1 represent a significant advancement in hydraulic motor technology, providing a combination of strength, adaptability, and performance. Whether utilized in agricultural equipment, construction machinery, or industrial settings, these motors are built to deliver dependable and efficient performance, ensuring operational excellence in a variety of hydraulic systems.

ALUMINIUM GEAR MOTOR 2SM - GROUP 2

The 2SM Series motors from Group 2 are meticulously engineered to offer versatility and robust performance, featuring unidirectional and reversible capabilities. These three-piece constructed motors are built with an aluminum body and flanges, designed to meet the demands of a wide range of industrial applications.

Adaptable Design for Multiple Configurations: The 2SM motors provide a broad selection of shafts and flanges, accommodating various equipment needs and ensuring seamless integration into different systems. The option for configurations with integrated valves allows for a more compact design, reducing the complexity and potential cost of additional hydraulic components.

Suitable Displacement Range for Varied Applications: With displacements ranging from 4 cm³/rev to 31.5 cm³/rev (from 0.24 in³/rev to 1.92 in³/rev), the 2SM Series can be tailored to specific system requirements. This range facilitates precise adjustment of motor output, accommodating both low and high flow applications.

High-Pressure Performance: The 2SM motors are capable of operating under pressures of up to 250 bar (3600 psi), providing consistent and reliable power in high-pressure situations. This feature makes them well-suited for heavy-duty operations where robust motor action is essential.

Efficient High-Speed Operation: Capable of reaching rotational speeds up to 4000 rpm, these motors are designed for applications that benefit from quick response and high-speed action. The performance at such speeds demonstrates the motors' capacity to handle dynamic tasks efficiently.

In summary, the 2SM Series from Group 2 offers a powerful combination of durability, flexibility, and performance. Whether they're used in mobile machinery, agricultural equipment, or industrial processes, these motors are engineered to deliver reliable and efficient operation, making them a valued component in any hydraulic system.

ALUMINIUM GEAR MOTOR 2XM - GROUP 2

The 2XM Series from Group 2 presents a new range of unidirectional and reversible motors, built with the robustness of three-piece construction, combining an aluminum body with cast iron flanges. These motors are designed to offer superior performance, particularly in mobile equipment that undergoes heavy-duty operating cycles.

Oversized Shafts for Heavy-Duty Performance: The 2XM motors are equipped with oversized shafts, which provide increased strength and durability. This design enhancement makes them especially suited for installations in mobile equipment that demand resilience and reliability during intensive use.

Diverse Flange Options for Versatility: With a wide selection of flanges, the 2XM motors offer a high degree of compatibility, ensuring they can be tailored to fit a broad array of mobile machinery and systems.

Integrated Valve Configurations for Streamlined Systems: The option for integrated valve configurations within the 2XM Series allows for more compact system designs, which can simplify the hydraulic circuit and potentially enhance overall system efficiency.

Optimal Displacement for Varied Applications: The displacement range for the 2XM Series stretches from 4 cm³/rev to 31.5 cm³/rev (from 0.24 in³/rev to 1.92 in³/rev), providing the flexibility needed to meet the flow and speed requirements of a diverse set of hydraulic systems within Group 2 specifications.

High-Pressure and High-Speed Capabilities: These motors are capable of handling pressures up to 250 bar (3600 psi) and can achieve rotational speeds of up to 4000 rpm. Such specifications cater to the demands of heavy-duty applications that require robust motor action and high-speed performance.

In essence, the 2XM Series motors from Group 2 are a testament to hydraulic engineering excellence, offering a solution that meets the rigorous demands of heavy-duty mobile equipment. They provide a blend of power, durability, and flexibility, ensuring dependable and efficient operation across various industrial applications.

ALUMINIUM GEAR MOTOR 3GM - GROUP 3

The 3GM Series from Group 3 is a robust selection of unidirectional and reversible motors, which are constructed from three sturdy pieces that include an aluminum body and cast iron flanges. These motors are specifically engineered to provide exceptional performance and reliability for a variety of industrial and mobile applications.

Durable and Versatile Construction: The combination of aluminum and cast iron in the 3GM motors offers a balance of lightweight design and durability. This construction is suited for heavy-duty operations, ensuring longevity even under strenuous conditions.

Wide Range of Customization Options: A broad array of shafts and flanges allows these motors to be highly adaptable to different equipment specifications, providing the flexibility needed to meet a wide range of application demands.

Integrated Valve Configurations: The availability of configurations with integrated valves facilitates a more efficient design by potentially reducing the hydraulic system's complexity and the number of external components needed.

High Displacement Range: With displacement options ranging from 19.3 cm³/rev to 77.2 cm³/rev (from 1.2 in³/rev to 4.7 in³/rev), the 3GM Series can cater to various flow requirements, offering the capability to deliver both high torque at low speeds and maintain efficiency at higher speeds.

Pressure and Speed Capabilities: The 3GM motors are capable of withstanding pressures up to 250 bar (3600 psi) and can achieve rotational speeds of up to 3500 rpm. These characteristics make them well-suited for applications that demand robust power delivery and high-speed operations.

In summary, the 3GM Series from Group 3 offers a potent combination of durability, adaptability, and performance. These motors are designed to deliver reliable and efficient operation, making them an excellent choice for a variety of applications, including but not limited to agricultural machinery, construction equipment, and industrial processes. Their construction and features ensure they are up to the task of powering heavy-duty operations while providing the flexibility to integrate seamlessly into numerous hydraulic systems.

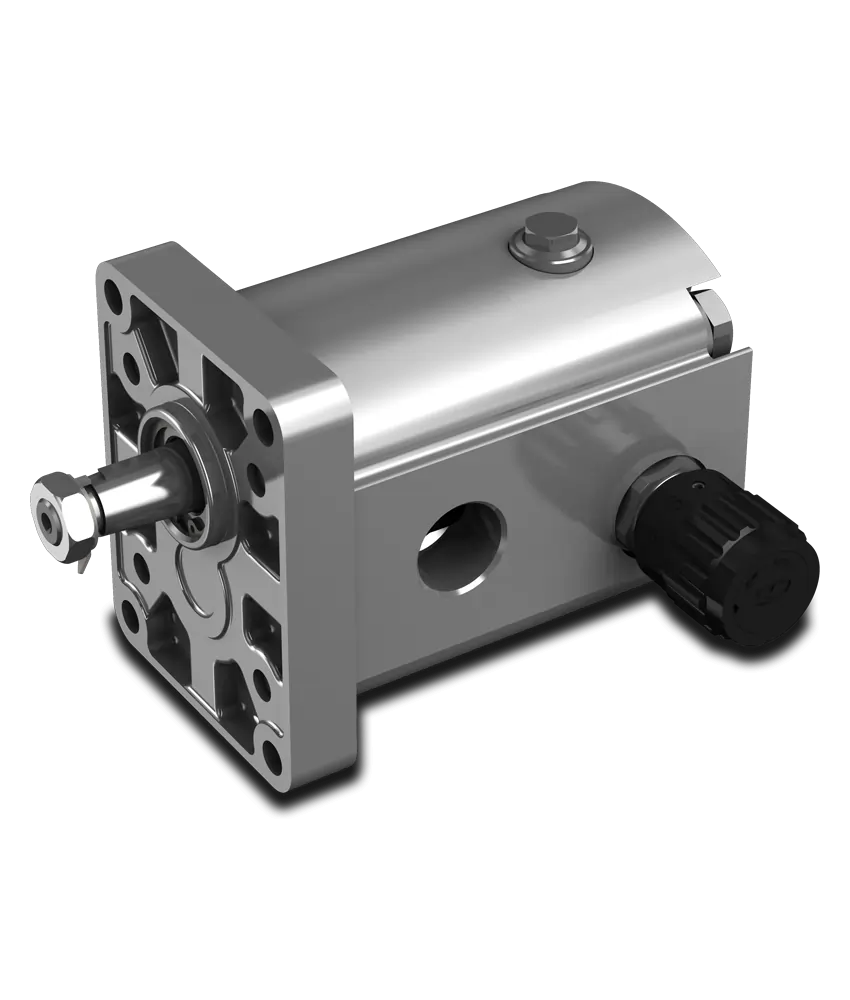

GEAR FLOW DIVIDERS

Gear flow divider 1SF - GROUP 1

The 1SF Series within Group 1 encompasses a range of SF1 flow dividers, distinguished by their aluminum bodies and flanges. These flow dividers are designed to efficiently distribute flow and pressure across multiple actuator lines within hydraulic systems.

Versatile Displacement Options: The 1SF Series offers a selection of displacement sizes ranging from 1.18 cm³/rev to 7.76 cm³/rev (from 0.07 in³/rev to 0.47 in³/rev), which allows for precise flow division to suit various operational demands and application needs.

On-Demand Customization with Relief Valves: Available with the option of relief valves for actuator rephasing upon request, these flow dividers can provide added safety and control, ensuring consistent performance and protection against overpressure conditions.

High-Pressure Capacity for Demanding Applications: The 1SF Series flow dividers are rated for maximum pressures of up to 260 bar (3750 psi), making them suitable for high-pressure systems where accurate flow distribution is critical.

High-Speed Rotation for Responsive Operation: Capable of operating at speeds of up to 4800 rpm, the 1SF Series is designed to accommodate systems requiring fast and responsive flow management.

Scalability with Multiple Sections: With the ability to support up to 6 sections, these flow dividers offer scalability and flexibility, making them ideal for complex hydraulic circuits that service multiple functions or actuator lines.

In essence, the 1SF Series from Group 1 provides a reliable and precise solution for hydraulic flow division, delivering customizable options to enhance system functionality. Whether for industrial, mobile, or agricultural applications, these flow dividers are engineered to integrate seamlessly, ensuring efficient and balanced hydraulic operations.

Gear flow divider 2SF – GROUP 2

The 2SF Series from Group 2 presents a sophisticated line of SF2 flow dividers, characterized by their durable aluminum bodies and flanges. These devices are tailored to meet the needs of various hydraulic systems, offering precise flow division and control.

Displacement Range for Diverse Applications: With displacements available from 4 cm³/rev to 26 cm³/rev (from 0.24 in³/rev to 1.59 in³/rev), the 2SF Series can accommodate a broad spectrum of flow rates, making these flow dividers suitable for a wide range of hydraulic applications.

Customizable with Relief Valves: On-demand, these flow dividers can be equipped with relief valves for actuators rephasing. This feature provides additional safety and functionality, ensuring that hydraulic systems can maintain balanced and phased operations, especially in applications requiring synchronized movement of actuators.

High-Pressure Operation: Engineered to handle pressures up to 260 bar (3750 psi), the 2SF Series is well-suited for high-pressure environments, offering reliability and performance consistency across various hydraulic tasks.

High-Speed Capabilities: With the ability to operate at speeds up to 4800 rpm, these flow dividers are designed for applications that demand quick and efficient flow distribution, ensuring responsive control and operation within hydraulic systems.

Versatility with Multiple Sections: The option to configure up to 6 sections provides flexibility in designing complex hydraulic circuits. This adaptability allows for tailored flow division solutions that can meet specific requirements of diverse hydraulic systems.

The 2SF Series from Group 2 embodies a perfect blend of performance, versatility, and reliability, making it an excellent choice for hydraulic systems requiring efficient flow division. Whether used in industrial machinery, mobile equipment, or other hydraulic applications, these flow dividers offer a solution that combines high-quality construction with the flexibility to meet the demands of various operational needs.

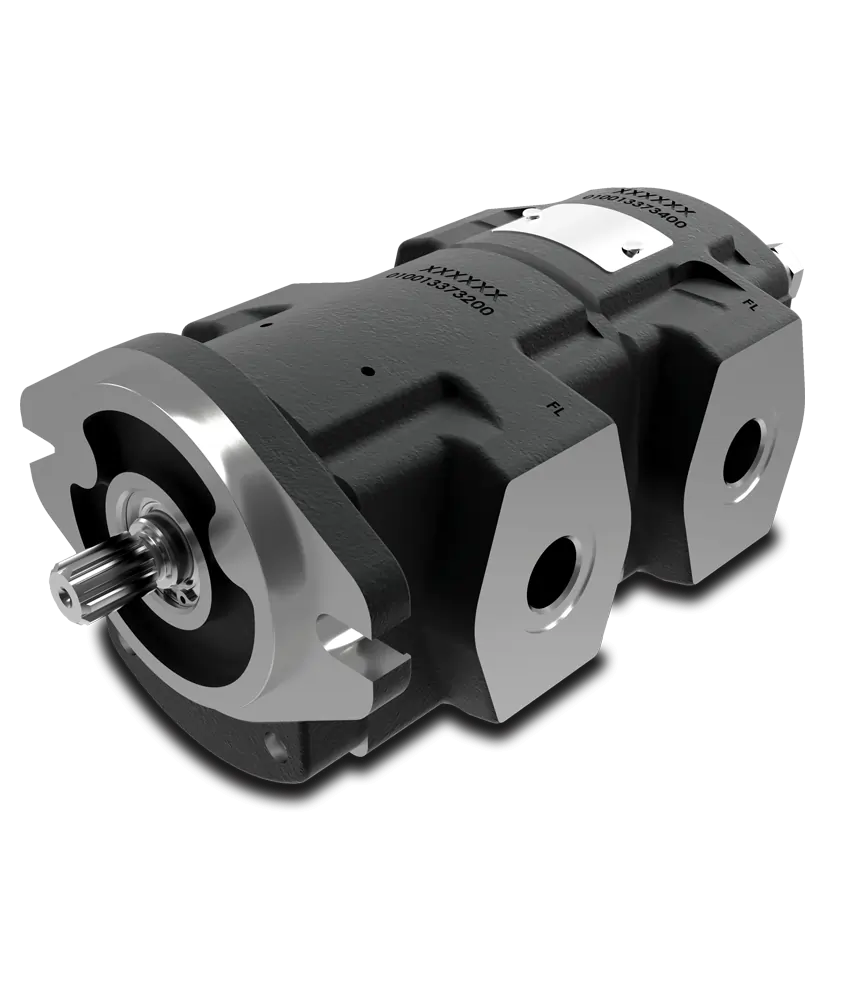

Cast iron gear Pumps

Cast iron gear Pump 2XPW - GROUP 2

The 2XPW series from Walvoil introduces a robust range of Cast Iron Pumps designed to surpass the performance of traditional aluminum pumps, especially in applications that push the limits of aluminum pump capabilities. These pumps are engineered for heavy-duty operating cycles typical in mobile equipment, where higher pressures and mechanical stresses are a norm.

Enhanced Durability for Heavy-Duty Applications: The choice of cast iron for the pump body significantly increases the pump's durability and resistance to wear, making the 2XPW series particularly suited for environments where operating conditions are harsh and demanding.

Modular Construction for Versatile Applications: Maintaining the modular construction familiar to the Group 2 series, these pumps offer the same versatility in terms of flanges, shafts, and integrated valve options. This ensures that the 2XPW series can be seamlessly integrated into a wide variety of hydraulic systems without compromising on the customization options available with aluminum body counterparts.

Increased Displacement Range: With displacement options ranging from 11 cm³/rev to 31.5 cm³/rev (from 0.68 in³/rev to 1.92 in³/rev), the 2XPW series is capable of accommodating a broad spectrum of flow requirements. This range allows for tailored hydraulic solutions, ensuring optimal performance across different applications.

High-Pressure Capability: Engineered to withstand pressures up to 270 bar (3900 psi), the 2XPW pumps are built to operate reliably in systems where high-pressure performance is critical. This high-pressure capacity makes them ideal for a range of industrial and mobile applications requiring robust hydraulic power.

Operational Efficiency at High Speeds: Capable of achieving rotational speeds of up to 3500 rpm, the 2XPW series ensures efficient hydraulic flow under a variety of operating conditions. This speed capability, combined with the pump's high displacement and pressure ratings, ensures optimal performance and responsiveness.

In summary, the 2XPW Cast Iron Pumps from Walvoil represent a significant advancement in pump technology for heavy-duty applications. Offering the durability of cast iron construction along with the versatility and high performance of the Group 2 series, these pumps are an ideal choice for demanding hydraulic systems where traditional aluminum pumps might fall short.

Cast iron gear Pump 3TPW - GROUP 3

The 3TPW series from Group 3 introduces a line of robust two-piece pumps featuring cast iron bodies and flanges, specifically designed to meet the needs of heavy-duty applications that exceed the capabilities of traditional aluminum pumps. This series is an ideal solution for mobile equipment and other applications facing high pressures and mechanical stresses.

Durable Construction for Heavy-Duty Use: The use of cast iron for both the body and flange provides superior durability and resistance against wear and deformation under high-pressure conditions. This makes the 3TPW series especially suitable for environments where equipment is subjected to rigorous operating cycles.

Flexible Configuration Options: Available in both single and multiple pump configurations, these pumps offer the flexibility to be adapted to various system requirements. The ability to stack with pumps from different families further enhances this versatility, making it easier to customize hydraulic systems to specific needs.

Broad Range of Displacement Options: With displacements ranging from 23.9 cm³/rev to 79.8 cm³/rev (from 1.46 in³/rev to 4.87 in³/rev), the 3TPW series can accommodate a wide spectrum of flow rates. This range ensures that the pumps can be optimized for a variety of applications, from small machinery to large industrial systems.

High-Pressure Performance: Capable of operating at pressures up to 300 bar (4350 psi), the 3TPW series is designed to handle the demands of systems where high pressure is a key factor. This high-pressure capability makes the pumps suitable for a range of intensive applications, ensuring reliable performance under challenging conditions.

Efficient Operation at High Speeds: With a maximum rotational speed of up to 3000 rpm, these pumps are built to provide efficient and effective hydraulic flow across a broad range of operational speeds. This speed capacity allows for responsive and dynamic system performance, critical in many industrial and mobile applications.

Integrated Valve Options for Enhanced Functionality: The availability of configurations with integrated valves offers the potential for streamlined system design, reducing the complexity and the number of external components required. This feature can contribute to more compact and efficient hydraulic systems.

In summary, the 3TPW series from Group 3 is engineered to deliver high durability, flexibility, and performance in demanding applications. Its cast iron construction, combined with a wide range of configuration options and high-pressure capabilities, makes it an excellent choice for hydraulic systems requiring robust, reliable pumps capable of withstanding the rigors of heavy-duty operation.

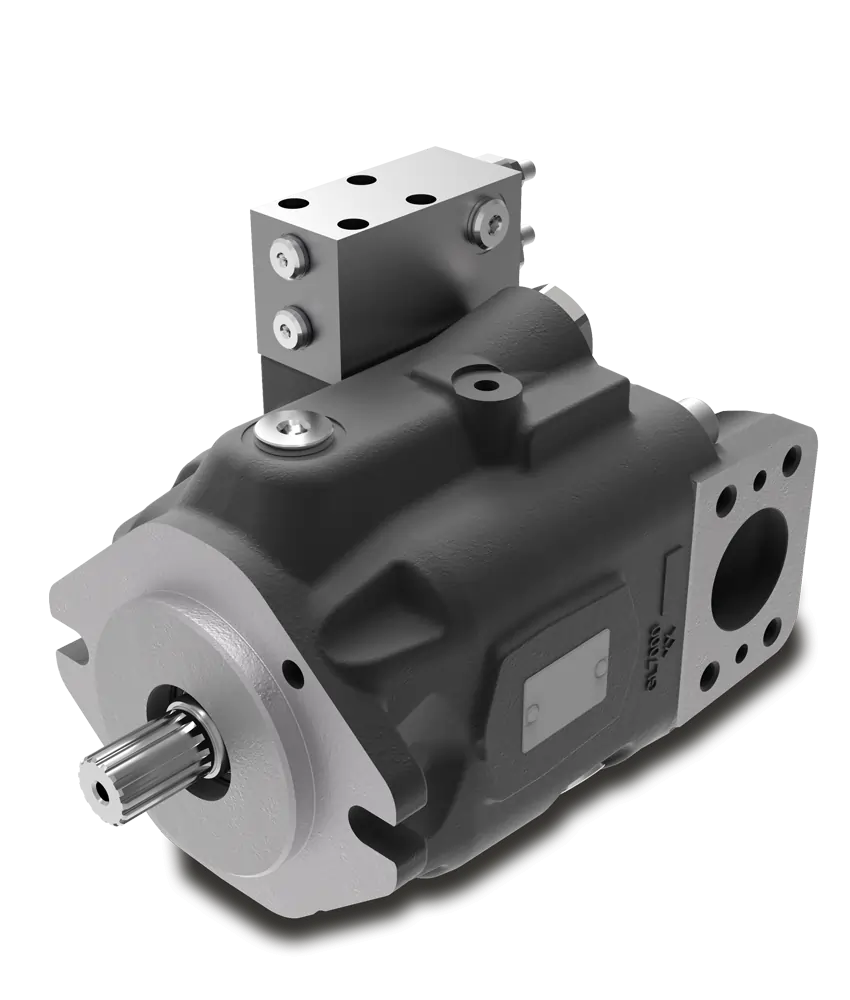

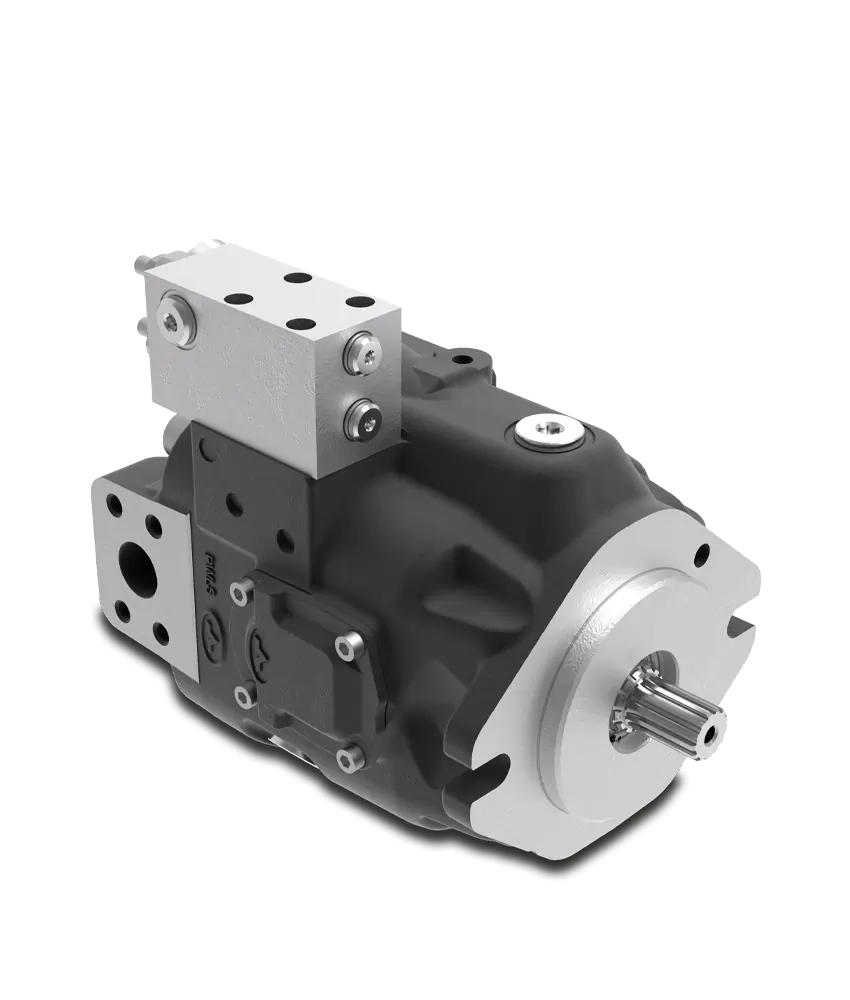

VARIABLE DISPLACEMENT PISTON PUMP

Variable Displacement Piston Pump PWLS7

The PWLS7 series by Walvoil introduces a cutting-edge range of Variable Displacement Piston Pumps, embodying the pinnacle of design and engineering for modern mobile hydraulic implements. These pumps are crafted to meet the dynamic needs of new-generation hydraulic systems, ensuring efficiency, reliability, and operational comfort.

Compact and Efficient Design: The PWLS series is distinguished by its compact design, which facilitates installation in tight spaces often found in mobile equipment. This compactness does not compromise its performance, making it an ideal solution for a wide array of machinery.

Optimized for Operator Comfort: The reactivity and stability of the PWLS pumps are engineered to provide maximum comfort for the operator, ensuring smooth and consistent hydraulic performance that translates to precise control over machinery and implements.

Robust for Heavy-Duty Applications: Designed for heavy-duty operation within the medium pressure range, the PWLS pumps boast a nominal service pressure of up to 280 bar (4050 psi). This capability makes them suitable for a variety of demanding environments and tasks.

Advanced Features for Modern Systems: Equipped with additional features such as sensors cavities, compact tandems, and various control manifolds, the PWLS series offers a comprehensive solution for advanced hydraulic systems. These features enhance the versatility and functionality of the pumps, allowing for integration into sophisticated hydraulic circuits.

Versatile Application Range: The typical applications for the PWLS pumps are diverse, covering construction machinery such as Skid Steer Loaders, Telehandlers, and Excavators, as well as lifting and transport equipment like Aerial Lifts and Fork Lifts. This versatility underscores the pump's adaptability to different hydraulic system requirements.

Performance Specifications: With displacement options ranging from 56 cm³/rev to 80 cm³/rev (from 3.41 in³/rev to 4.88 in³/rev) and the ability to operate at speeds of up to 3000 rpm, the PWLS pumps are designed to deliver optimal hydraulic flow and performance under various conditions.

In essence, the PWLS7 series from Walvoil represents a leap forward in piston pump technology, offering a blend of compact design, operational comfort, and heavy-duty performance. These pumps are poised to set a new standard for mobile hydraulic systems, providing a reliable and efficient solution for today's high-demand applications.

Variable Displacement Piston Pump PWLS5

The PWLS5 series from Walvoil introduces a groundbreaking range of Variable Displacement Piston Pumps tailored for the evolving requirements of mobile hydraulic systems. This series encapsulates the innovation and expertise of Walvoil in developing hydraulic solutions that enhance performance, ensure durability, and optimize user experience across a broad spectrum of mobile applications.

Designed for Compact Spaces: The PWLS5 pumps are distinguished by their compact design, enabling easy installation in the confined spaces typical of modern mobile machinery. This compactness is a critical advantage, allowing flexibility in design and application without compromising on hydraulic power or efficiency.

Optimal Operator Comfort: Reactivity and stability are at the forefront of the PWLS5's design philosophy, providing maximum comfort for the operator. These pumps are engineered to deliver smooth and responsive control, ensuring precise operation of machinery with reduced operator fatigue.

Heavy-Duty Performance: With a nominal service pressure capacity of up to 280 bar (4050 psi), the PWLS5 series is built for heavy-duty operations within the medium pressure range. This capability ensures reliable performance under the demanding conditions typical of construction sites and other intense work environments.

Advanced Features for Enhanced Functionality: The series is equipped with advanced features such as sensor cavities, compact tandems, and various control manifolds. These additions offer a higher level of control and versatility, enabling the integration of the pumps into complex hydraulic systems with ease.

Broad Application Range: The PWLS5 pumps are designed for a wide array of applications, from construction machinery like Skid Steer Loaders, Telehandlers, and Excavators, to lifting and transport equipment such as Aerial Lifts and Fork Lifts. This versatility makes the PWLS5 series an ideal choice for a multitude of hydraulic systems requiring variable displacement and precise control.

Performance Specifications: Offering displacement options from 41 cm³/rev to 56 cm³/rev (from 2.50 in³/rev to 3.41 in³/rev) and operational speeds of up to 3000 rpm, the PWLS5 pumps are designed to meet the needs of various hydraulic applications, providing efficient and effective fluid power.

In conclusion, the PWLS5 series represents Walvoil's commitment to innovation and excellence in hydraulic pump technology. These Variable Displacement Piston Pumps are a testament to Walvoil's dedication to providing solutions that meet the rigorous demands of modern mobile equipment, ensuring high performance, reliability, and operator satisfaction.

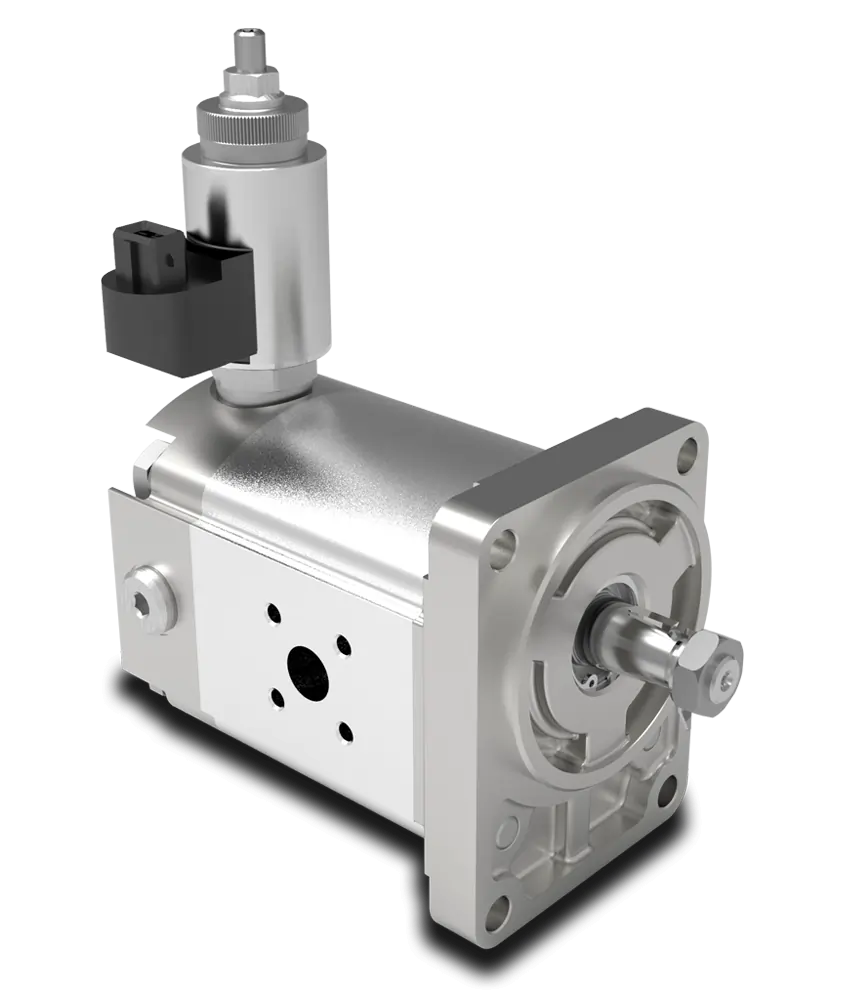

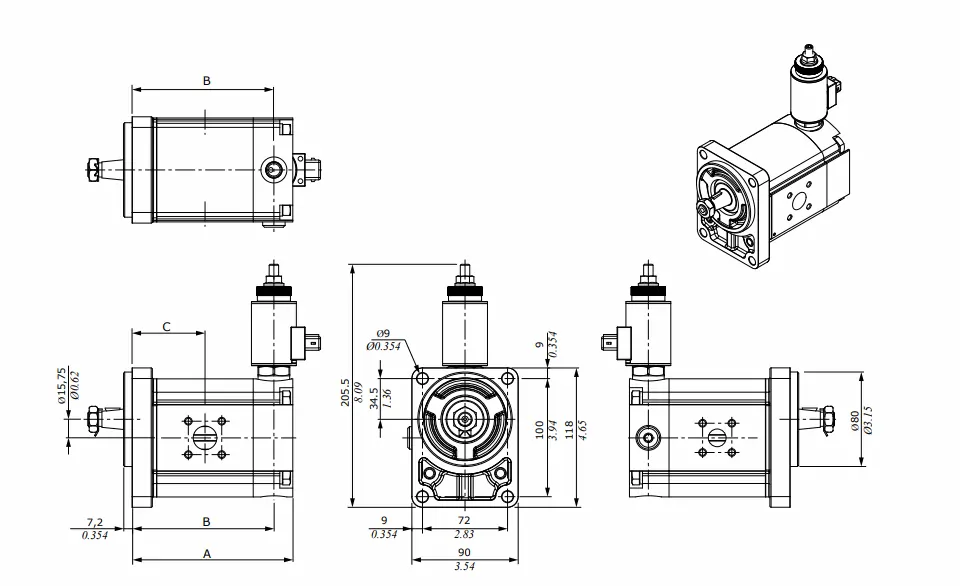

FAN DRIVE

WALVOIL FAN DRIVE

The Walvoil Fan Drive introduces an innovative approach to vehicle cooling systems, utilizing external gear motors renowned for their efficiency, longevity, and minimal maintenance requirements. This new range signifies a leap in cooling technology, offering a sophisticated alternative to traditional electric or belt drive systems.

Advantages Over Traditional Cooling Systems: The use of electrohydraulic Fan Drives brings several key benefits when compared to conventional cooling solutions. These include enhanced performance, reduced maintenance costs, and increased service life, making them particularly appealing for modern hydraulic systems.

Optimized Performance with Electronic Control: The Fan Drive system reaches its maximum potential when integrated with the Walvoil CED400W electronic control units. These fully programmable units allow for precise control over the cooling process, adapting the fan speed dynamically to meet the cooling demands of the vehicle in real-time. This results in improved efficiency and reduced energy consumption.

Flexible Displacement Range for Varied Applications: With displacement options ranging from 4 cm³/rev to 31.5 cm³/rev (from 0.24 in³/rev to 1.92 in³/rev), the Walvoil Fan Drive can accommodate a wide spectrum of flow requirements. This versatility ensures that the cooling system can be tailored to different vehicle sizes and needs, from small utility vehicles to large industrial machinery.

High-Pressure and Speed Capabilities: Designed to operate at pressures up to 250 bar (3600 psi) and speeds up to 4000 rpm, the Walvoil Fan Drive is capable of handling the demanding requirements of vehicle cooling systems. This high-pressure and speed capacity allows for effective temperature regulation, ensuring optimal performance of the vehicle under various operating conditions.

In essence, the Walvoil Fan Drive system represents a significant advancement in vehicle cooling technology, offering a reliable, efficient, and customizable solution that surpasses traditional cooling methods. Its integration with advanced electronic controls further enhances its performance, making it an ideal choice for a wide range of applications seeking to improve cooling efficiency and system longevity.

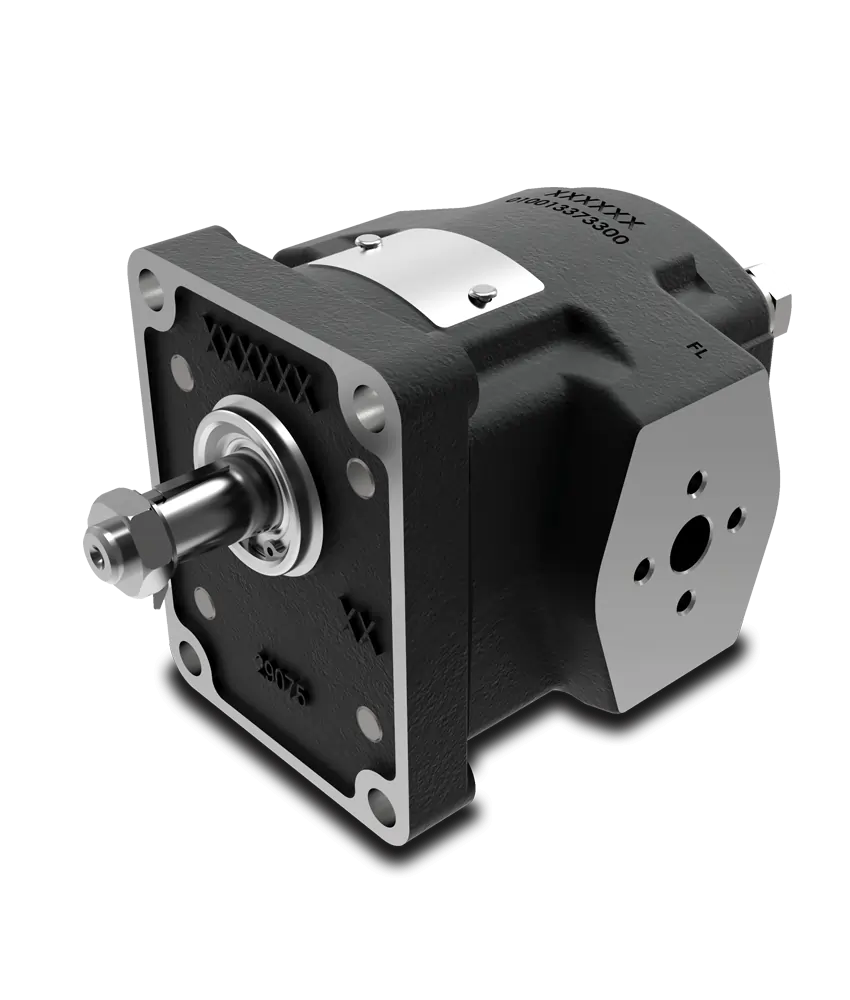

Cast iron gear motors

CAST IRON GEAR MOTOR 2XMW - GROUP 2

The motors described offer a robust and versatile solution for a wide array of hydraulic applications within Group 2, characterized by their unidirectional and reversible functionality. Constructed with cast iron for both the flanges and body, these motors are designed to withstand the rigorous demands of industrial and mobile equipment, ensuring durability and longevity even under challenging conditions.

Durable Construction for Heavy-Duty Use: The choice of cast iron for the body and flanges enhances the motor's resistance to wear and tear, making it particularly suited for applications where durability and reliability are paramount. This heavy-duty construction is ideal for environments experiencing high pressures or mechanical stresses.

Flexibility in Configuration: With a wide selection of shafts and flanges, these motors can be adapted to fit a variety of system requirements, ensuring seamless integration into existing setups. The availability of configurations with integrated valves further adds to the motor's versatility, allowing for a more streamlined and efficient hydraulic system design.

Wide Displacement Range: Offering displacements from 11 cm³/rev to 31.5 cm³/rev (from 0.68 in³/rev to 1.92 in³/rev), these motors provide the flexibility needed to accommodate a broad spectrum of flow rates and operational demands. This range enables precise control over motor speed and torque, making it suitable for a diverse set of applications.

High-Pressure Capability: Capable of operating at pressures up to 270 bar (3900 psi), these motors are designed to perform reliably in systems where high-pressure capacity is critical. This feature ensures that the motors can deliver the required power and performance for a variety of industrial and mobile applications.

High-Speed Operation: With the ability to reach speeds of up to 3500 rpm, the motors are well-equipped to handle applications requiring fast and efficient power delivery. This high-speed capability allows for responsive and dynamic system performance, essential in many modern hydraulic applications.

In summary, these Group 2 unidirectional and reversible motors with cast iron construction offer a high-performing, durable, and versatile solution for a wide range of hydraulic systems. Their robust design, combined with a flexible range of configurations and high-pressure capabilities, makes them an ideal choice for applications demanding reliable and efficient hydraulic power.

CAST IRON GEAR MOTOR 3TMW - GROUP 3

The 3TMW series from Group 3 is a robust collection of two-piece motors featuring cast iron bodies and flanges, designed to exceed the capabilities of traditional aluminum motors in demanding applications. These motors are specifically engineered to deliver reliable performance in heavy-duty operating cycles, making them an ideal choice for mobile equipment facing high pressures and mechanical stresses.

Enhanced Durability for Heavy-Duty Applications: The use of cast iron for both the body and flange significantly increases the motor's durability, offering superior resistance against wear and the harsh conditions typical of heavy-duty environments. This material choice ensures that the motors can withstand the rigors of intensive use without compromising performance.

Versatile Configuration Options: With a wide selection of shafts and flanges, the 3TMW motors offer extensive adaptability to fit a broad range of system requirements. The availability of configurations with integrated valves adds to the motor's versatility, allowing for a more compact and efficient system design by reducing the need for external components.

Broad Displacement Range: Offering displacements from 23.9 cm³/rev to 79.8 cm³/rev (from 1.46 in³/rev to 4.87 in³/rev), these motors can accommodate various flow requirements. This range enables precise control over motor output, making the 3TMW series suitable for a wide array of hydraulic systems and applications.

High-Pressure and Speed Capabilities: Designed to operate at pressures up to 300 bar (4350 psi) and capable of reaching speeds of up to 3000 rpm, the 3TMW motors are equipped to handle the demands of systems where high pressure and speed are critical. This capability ensures efficient and effective performance across a spectrum of operational conditions.

Ideal for Challenging Environments: The 3TMW series is particularly suited for applications where traditional aluminum motors may fall short, such as in mobile equipment intended for heavy-duty operating cycles. The motors' robust construction and high-pressure tolerance make them a reliable choice for applications involving high mechanical stresses.

In summary, the 3TMW series from Group 3 offers a powerful, durable, and versatile solution for hydraulic systems requiring motors that can withstand heavy-duty operations. Their robust design, combined with a flexible range of configuration options and high-performance capabilities, makes them an ideal choice for a wide range of industrial and mobile applications demanding reliability and efficiency.