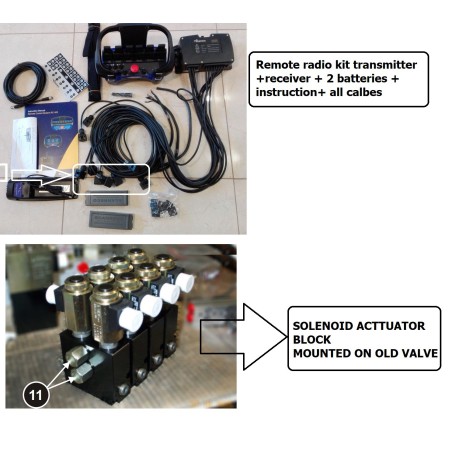

RC400 RADIO REMOTE CONTROLLER 4 FUNCTION + HYDRAULIC MODULES FOR HYDROCONTROL VALVE 12VDC OR 24 VDC

Power supply: 12V or 24V

Functions: 4

Max thrust: 1300 N (at 30 bar)

Connections: G1/4" BSPP

- Share this:

- Secured Payment

- Fast Delivery

- 24/7 Tech Support

RC400 RADIO REMOTE CONTROLLER 4 FUNCTION + HYDRAULIC MODULES FOR HYDROCONTROL VALVE 12VDC OR 24 VDC

- Touch on Image to show all photos

Power supply: 12V or 24V

Functions: 4

Max thrust: 1300 N (at 30 bar)

Connections: G1/4" BSPP

Informations

RC400 radio remote controller 4 function + hydraulic modules for hydrocontrol valve 12VDC or 24 VDC.

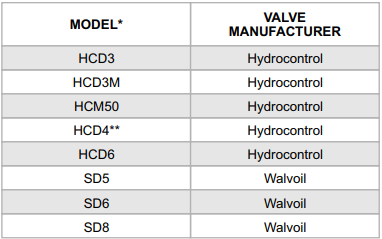

Proportional actuator blocks for direct connection on HCD (HYDROCONTROL) and SD (WALVOIL) hydraulic valves, were born to allow the remote control of a machine, which has these kinds of manual hydraulic valves: each module for HCD-SD that is part of the block can control one proportional function.

The direct installation on the back of the hydraulic valve guarantees the possibility for the user to make a very “precise” mounting, in a “limited” place. In this way risk of any eventual future “mechanical plays” is excluded.

The servo control HC-SD is a block of modular hydraulic pistons, electrically controlled by a couple of proportional valves, with mechanical feedback.

The product has a high reliability thanks to careful engineering and production process carried out with the most advanced technologies.

The installation of this block adds to a manual hydraulic valve the remote control, by cable or by radio.

The specific design made for the direct connection to the back of the valve allows a more precise handling of the machine compared to traditional installations of retrofit modules on the dual control rods.

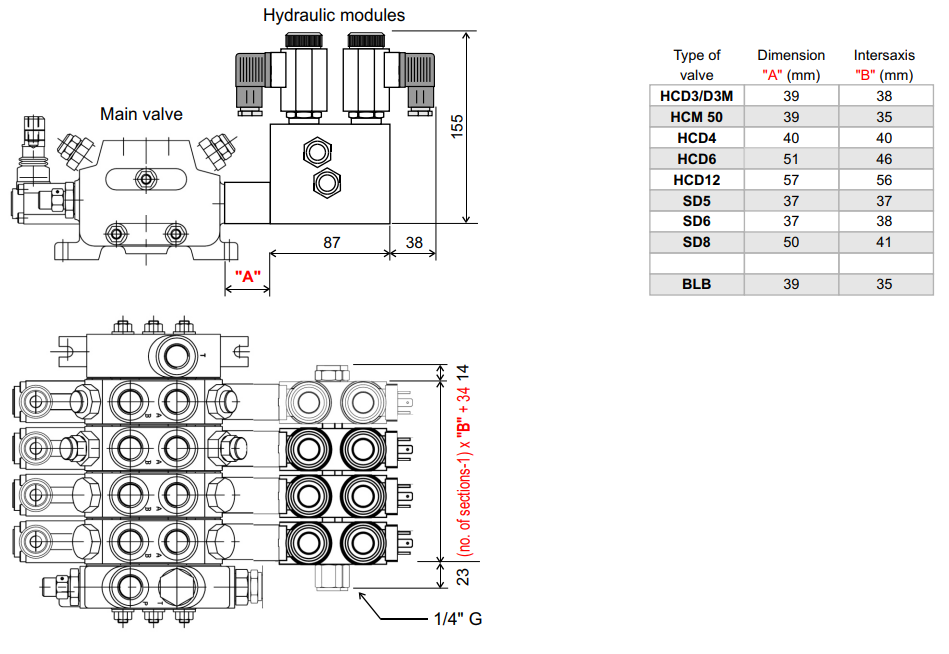

Assembled banks are available up to 8 functions, without spaces between sections.

Electrical specifications:

Power supply: 12V or 24V

Working current range:

600 ÷ 1600 mA (12V)

230 ÷ 830 mA (24V)

Frequency: 60 Hz

Working temp. range: -20 ÷ +60 °C

Hydraulic / mechanical specifications:

Feedback: Mechanical

Fluid type: Mineral oil 10 ÷ 200 cSt

Filtration: 10 micron

Max blow-by: 100 cc/minute

Max working pressure: 30 bar

Weight (each section): 1.6 kg approx. (per section)

Banks are available for the following manufacturers:

|

Overall dimensions:

To add a section to the block:

- Place the block on a surface or a container that can detain the oil leaked from the parts during the assembly operations.

- Unscrew the two drilled terminals (11) with a monkey wrench of 19 mm.

- Remove the blind terminals (12) from the block.

- Place the new sections next to the others remembering to put the couple of brass rings (13) between each section, in correspondence of the modules

lateral holes (8). Verify that these holes must have the O-Ring.

- Use the new blind terminals included in the kit and insert them between the

sideways holes following the direction shown in figure 1 and 2. Be sure to cross also the brass rings.

- Screw the two drilled terminals to tighten together the modules.

To fix the block of modules to the valve:

- Insert the two brass bushes (1) in the spring (2) as shown in figure 4.

- Insert the space washer (3) into the right brass bush (2). NOTE: this washer is not included in the kit, use the washer located on the section of the HCD valve

where the module will be mounted.

- Insert the spring and the two brass bushes in the aluminium cube (4) and fix them to the valve with two M5x40 screws (5) using a setscrew wrench

of 4 mm.

- Repeat the previous operations for each section.

- Unscrew the plug (9) from the back of the module (setscrew wrench of 5 mm).

- Lock the screw inside the hole to fix the piston (6) to the valve (setscrew wrench of 4 mm). The piston must across the space washer (3).

- Repeat the previous two operations for each section.

- Fix the module body (7) to the aluminum cube with two M5x90 screws (10) using a setscrew wrench of 4 mm.

- Repeat the previous operation for each section

Scanreco RC400 Radio Remote Control Systems.

The Scanreco RC 400 G2B remote control system has been especially developed for

hydraulically driven mobile cranes and machinery. The system is a digital remote

control system based on an extremely advanced microprocessor technology. Years of

exhaustive and demanding testing have shown that the remote control system can

cope with the roughest of environments.

The system is protected against electromagnetic and radio frequency radiation and

can be installed onto all hydraulic valve types (voltage, current pulse width, or

protocol steered) found on the market.

In its basic form the remote control system is comprised of a portable control unit

with manoeuvre levers for proportional control and switches for ON/OFF functions, a

central unit with connection cable for driving proportional electro-hydraulic slide

controllers.

Digitally coded control information (lever deflection and switch position) is sent from

the portable control unit via radio to the central unit. The portable control unit and

central unit translate the magnitude and direction of the manoeuvre lever deflections

and switch position.

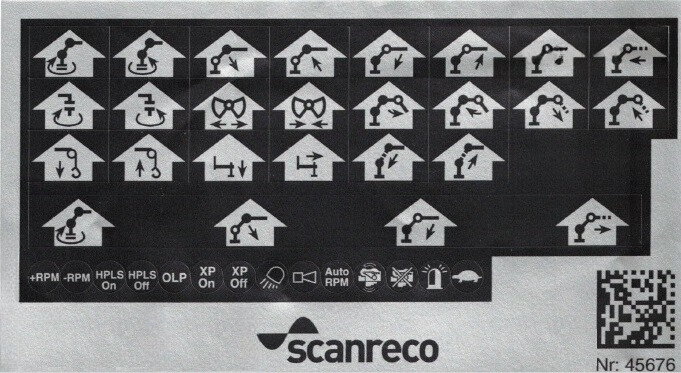

It can be used for six typical proportional functions, e.g.

-Slewing (rotation of crane)

-Main lift

-Jib

-Extension

-Grab open / close

-Rotator

You can also choose a different function as below:

|

The "Mini" is a compact and versatile transmitter that can be easily adapted to customer requirements. Thanks to its modular design, the "Mini" can be supplied with either 1 to 6 linear levers or 1 to 3 joysticks and additional buttons and switches. Despite the compact format, all operating elements are sufficiently large and designed for long and fatigue-free operation.

In addition to standard functions, the transmitter also offers numerous optional settings and functions for optimum operator guidance. The speed of proportional movements can be set in five stages using a latching switch. The operator receives feedback from the controlled machine via the display and LEDs. Automatic frequency management ensures trouble-free operation even in the event of interference from other radio devices in the vicinity. On-site calibration allows authorized users to adjust system settings without additional tools or software. The transmitter has an individual identification code and communicates with the receiver via a proprietary protocol. This ensures that no other transmitters (from Scanreco or other manufacturers) can accidentally activate the machine. The tamping function complies with performance level "e" (PL e), the highest level according to ISO 13849-1, a legally binding standard for safety-critical control components.

|

The "G2" receiver is available with proportional and digital outputs as well as a CANopen interface. Thanks to its numerous interfaces and setting options, the "G2" is suitable for practically all mobile hydraulic applications. The analog output signals can control voltage and current-controlled hydraulic valve blocks. Several receivers can be connected together in a master-slave configuration if more functions are required than a single receiver can provide. The numerous functions of the integrated basic controller support a wide range of performance and functions. The basic controller makes it possible to dispense with numerous external electronic components (PLC, relays, diodes, etc.).

|

The portable control unit is impact and weather resistant and is light weight and compact. Controls are available for 4, 5, 6, 7 or 8 manoeuvre functions. The manoeuvre levers are fully proportional and have spring return to the zero position, i.e. a "dead-man’s-handle". The control unit has an emergency stop function which will immediately stop all movement . All manoeuvre levers are protected with a protective frame against unintentional activation and against mechanical damage. The control unit has multi-step micro-speed operation as standard enabling instantaneous temporary reduction of speed and it can also be equipped with a large number of switches for ON/OFF functions. A LED and sound signal are used to indicate such things as operating and battery status and for a simple and diagnostic fault finding. ( See picture of control unit ).

For quotation please contact with us at shop@hydraulic-master.com

Please send us photos of hydraulic valve and your crane we will prepare offer for you for plug and play kit.

Volume discounts

| Quantity | Unit discount | You Save |

|---|---|---|

| 5 | 10% | $2,450 |

| 10 | 15% | $7,350 |

| 20 | 25% | $24,500 |

Do you need help?

Looking for a non-standard product?