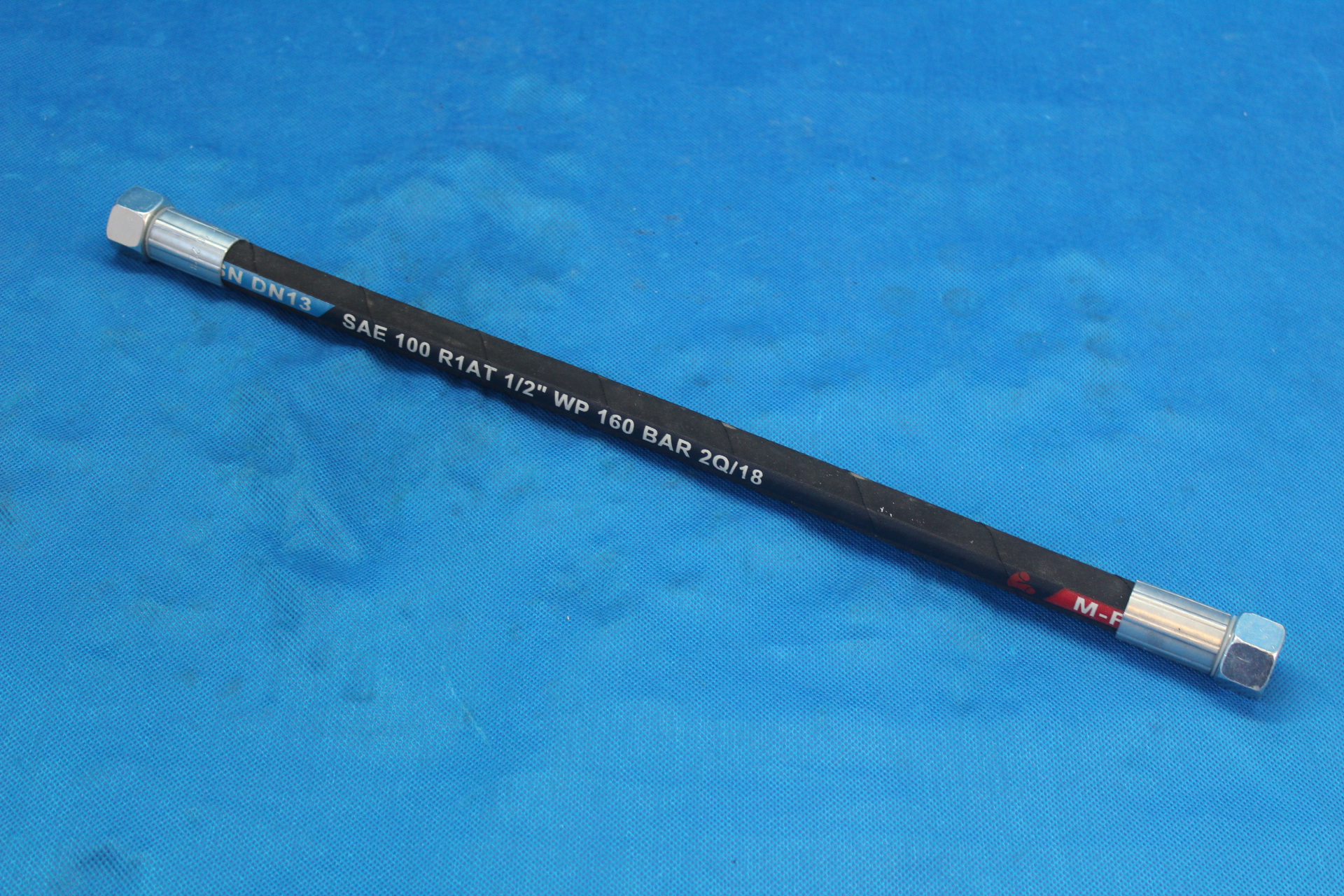

Hydraulic hose is the basic means of transporting liquids from one component to another, while at the same time providing innate versatility to designers.

A modern hydraulic hose usually consists of at least three parts: an inner tube that carries fluid, a reinforcing layer, and an outer layer.

No wonder that hydraulic hoses have a finite life. Proper selection and use of the right type of hose will certainly prolong the life of the hose assembly, but there are many different factors that affect hose life.

The tube is the inner part of the hose and is a lining that comes in contact with any carriers.

Due to this contact, the material used to build the pipe is important. If the chemical properties of the carrier are not compatible with the chemical properties of the pipes, the structural integrity of the entire hose will deteriorate. However, the purpose of the tube extends beyond the lining itself, which moves the fluid. The tube also acts as a protective measure against the outer layers of the hose.

If media passing through a pipe penetrates into other layers, an event called permeation, it can cause fluid loss as well as degradation of the outer layers.

There are three main projects to reinforce the hydraulic hose:

-

Helical

Screw reinforcement is used in applications where suction occurs. The spiral construction prevents the hose from collapsing and the entire flow is cut off.

-

Spiral

The spiral reinforcement works well in extremely high-pressure applications. Overlapping layers, usually made of steel wire, form a powerful layer that can withstand more aggressive applications.

-

Braid

The braided reinforcement layer is used primarily in applications with low or moderately high pressure. They can be made of one or more layers, so it is a very versatile construction with a reinforcing layer.

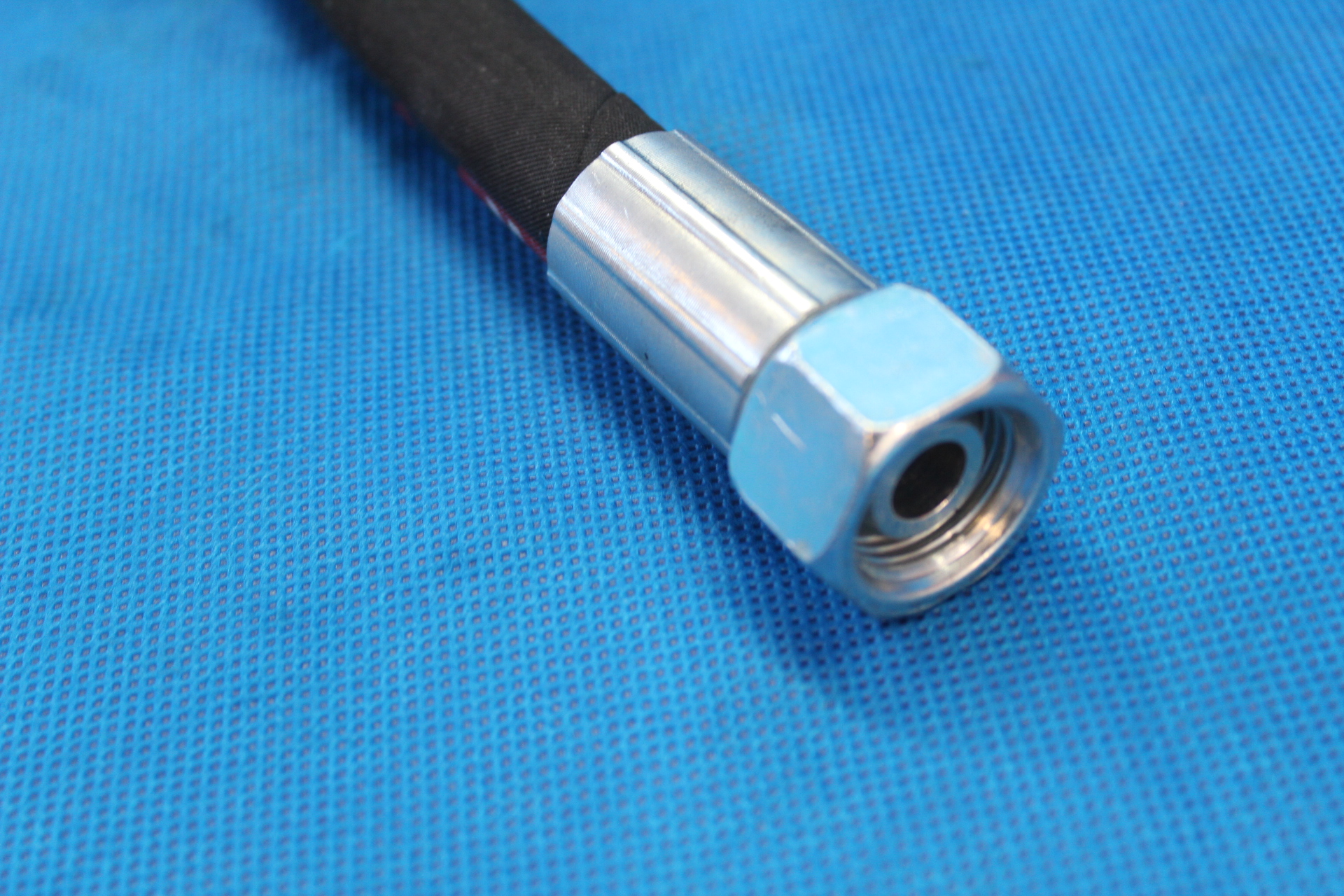

Once you understand the structure of the snake, choosing the right snake becomes equally important. Using the best hose and fittings for your application can improve the safety and efficiency of your entire team. Each element of the hose set is assessed individually, and the entire assembly is evaluated only as high as the component with the lowest rated value. This means that if the hose connectors are not as high as the hose, the overall assembly rating decreases.