We live in the ages when powerful hydraulic machines help do our work but what helps these machines do their work? The answer is a hydraulic pump and we will find out what is it in that article.

We can spot hydraulic pumps in hydraulic drive systems. They can be hydrostatic or hydrodynamic. A hydraulic pump converts mechanical power into hydraulic energy using mechanical energy such as for example fluid pressure. By the load at the pump outlet, It converts flow to overcome caused pressure. The hydraulic pump creates a vacuum at the entrance of itself which makes fluid from the tank go in. It creates mechanical moves and forces fluid go into the hydraulic system. Hydrostatic pumps are positive displacement pumps.

Hydrodynamic pumps can be positive displacement pumps, in which the displacement cannot be controlled. There may also be pumps with variable output, which have a more complicated structure that allows the offset to be adjusted. Hydrostatic pumps operate on the basis of Pascal's law.

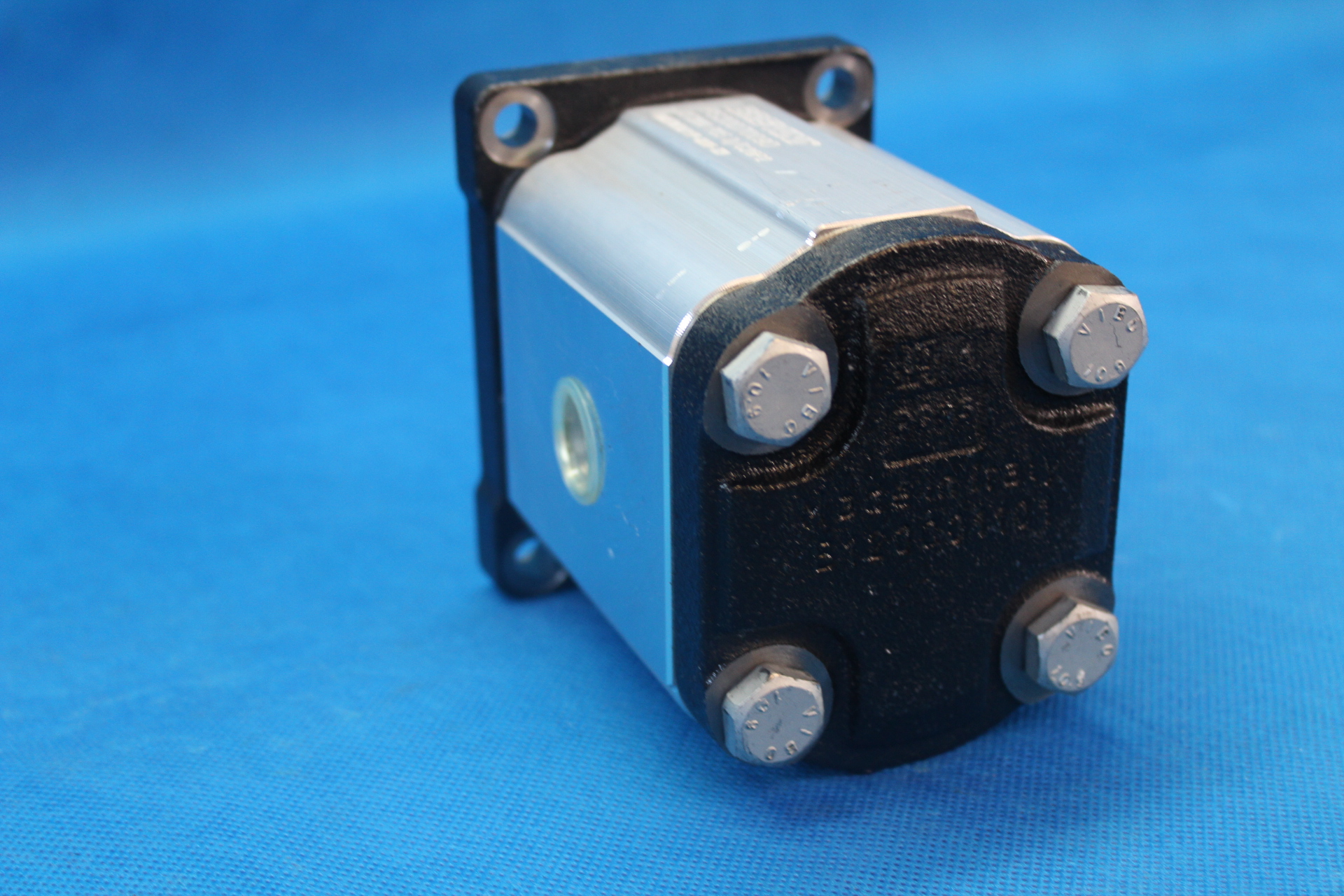

Gear pumps are simple and economical. The stroke volume or displacement of the gear pumps for the hydraulics will be between approximately 1 and 200 milliliters. They have the lowest volumetric efficiency of all three basic types of gear pumps, vane and piston pumps. These pumps generate pressure by engaging the gear teeth, which forces the fluid around the toothed wheels to increase pressure on the outlet side.

Spiral teeth of gears and higher tooth profiles with higher precision and quality, which shift and smooth out more smoothly, reducing the pressure wave are really common these days. Thanks to that, catastrophic breakdowns are a lot less frequent than in most other hydraulic pumps. The gears gradually wear out the housing and main sleeves. They gradually reduce the volumetric efficiency of the pump until it is unusable. This usually happens a long time before wear out, which causes the hydraulic pump to jam or break.

For lubrication, the gear pump uses a small amount of oil from the compressed side of the gears, drains them through (typically) hydrodynamic bearings and blows out the same oil either to the low-pressure side of the gears or through a special drain port on the pump housing.

The topic of the hydraulic pump is so extensive that it can not be included in one article. There are so many types and models in the world that you will surely meet your requirements and the best global standards.